involving网易yeah

网易yeah 时间:2021-02-16 阅读:()

APFIS2017-6thAsia-PacificConferenceonFRPinStructuresSingapore,19-21stJuly20171HaiFang,HuiyuanShi,WeiqingLiu,YujunQi,andRuiliHuoENHANCEMENTEFFECTANALYSISOFLATTICE-WEBSTOGFRP-WOODSANDWICHBEAMSINFLATWISEANDSIDEWISEBENDINGHaiFang1*,HuiyuanShi2,WeiqingLiu3,YujunQi4,RuiliHuo51Correspondingauthor,CollegeofCivilEngineering,NanjingTechUniversity,Nanjing,ChinaEmail:fanghainjut@njtech.

edu.

cn,WebPage:http://cce.

njtech.

edu.

cn/view.

aspid=527&class=2212SchoolofCivilEngineering,SoutheastUniversity,Nanjing,ChinaEmail:hyshiseu@yeah.

net3AdvancedEngineeringCompositesResearchCenter,NanjingTechUniversity,Nanjing,ChinaEmail:wqliu@njtech.

edu.

cn,WebPage:http://cce.

njtech.

edu.

cn/view.

aspid=485&class=2404CollegeofCivilEngineering,NanjingTechUniversity,Nanjing,ChinaEmail:qiyujun11@163.

com,WebPage:http://cce.

njtech.

edu.

cn/view.

aspid=1385&class=2215CollegeofCivilEngineering,NanjingTechUniversity,Nanjing,ChinaEmail:ruilihuo@njtech.

edu.

cnKeywords:GFRP-woodsandwichbeams,lattice-webreinforced,flexural,flatwise,sidewiseAbstractThispaperinvestigatestheflexuralbehaviorinflatwiseandsidewisepositionsofnovelgenerationcompositesandwichbeamswithPaulowniaandsouthernpinewoodcoreandglass-fiberreinforcedpolymer(GFRP)facesheetandlattice-webs.

Avacuumassistedresininfusionprocess(VARI)wasemployedtoformsandwichbeamswithdifferentnumbersofwebs.

Twocontrolwoodenbeamsandeighteenlattice-webreinforcedsandwichbeamsweresubjectedtofour-pointbendingteststodeterminetheirstiffness,capacity,andfailuremechanismsintheflatwiseandsidewisepositions.

Theexperimentalresultsrevealedthatthecompositesandwichbeamsfailedinflatwisebendingtestsunderlowerloadbutproducedagreaterdeflectioncomparedtothebeamsinsidewisebendingtests.

Withtheincreaseinthenumberoflattice-webs,ductilitywasfoundtoincreaseinflatwisepositionswhiledecreasinginsidewisepositions.

Analyticalformulasforcalculatingthebendingstiffness,capacity,andductilityoftheGFRP-woodsandwichbeamswereprovided,andtheanalysisresultsformechanicalperformanceshowedgoodagreementwiththeexperimentalresults.

1.

IntroductionComparedtotraditionalconstructionmaterials,themainbenefitsofGFRPcompositematerialinstructuralcomponentsareitshighstrength,excellentcorrosionresistance,easeofhandingandapplication,andflexibilityofdesign[1].

Inthispaperwepresentanewgenerationofcompositesandwichbeamsintendedforuseasloading-bearingcomponents.

Thecompositesandwichisintegrallyformedinthemoldbyavacuum-assistedresininfusionprocessinvolvingcompositeface-skins,webs,andcorematerials,asshowninFigure1.

Onenovelfeatureisthebundlingofthecorematerials,mainlycharacterizedbyhighstrength,intoinbothwebs.

Thesandwichbeams,thatclearlyenhancetheantistrippingandcooperativeperformancebetweensurfacelayerandcore,areconstructedbycloselywrappingwoodcorematerialstogetherusinglattice-websandface-skinsthatcangivefullplaytothepropertiesofthebendingandshearcapacityofthesandwichbeams.

Whenthesurfacelayerofthecompositesandwichbeamisundernormalload,themainfunctionofthewoodcoreistoimproveshapingandbearingandtoprovideelasticsupportsforthesandwichbeams.

Thecompositesandwichbeamavoidstheoccurrenceoflocalbucklinganddebonding,becausethecorematerialimprovesthedistributionofsectionstress,APFIS2017-6thAsia-PacificConferenceonFRPinStructuresSingapore,19-21stJuly20172HaiFang,HuiyuanShi,WeiqingLiu,YujunQi,andRuiliHuoeffectivelyreducingthestressconcentrationattheintersectionofthesurfacelayerandlattice-webs,significantlydelayingsplittingfailure.

Meanwhile,theGFRPlattice-webscaneffectivelyincreasethecapacityofshear,compression,andstripping,bothintheflatwise(horizontal)orinthesidewise(vertical)position.

Inthispaper,theultimatefailuremechanisms,initialbendingstiffness,load-deflectionbehaviorandstress-strainbehaviorofGFRP-woodsandwichbeamsunderfour-pointstaticbendingintheflatwiseandsidewisepositionsarereportedanddiscussed.

Thetheoreticaloutcomesforthestiffnessandstrengthofthecompositesandwichbeamsarealsopredictedandcomparedwiththeexperimentalresults.

(a)(b)(c)Figure1.

Lattice-webreinforcedcompositesandwichbeams(a)flatwise,(b)sidewise,and(c)cross-sectionalviewofrealobject.

2.

ExperimentalProgram2.

1.

TestSpecimensandMaterialsThestructuralsandwichbeamstestedinthisstudywereemployedusingGFRPskinsandlattice-webscomposedofbi-axial[0/90]glassfiberlaminates(800g/m2)andHS-2101-G100unsaturatedpolyesterresintowrapthecorematerialstogether.

High-classPaulowniaorsouthernpinewood,weighing280kg/m3and500kg/m3respectively,werefilledascorematerialsinthesespecimens.

Theoveralldensityofthecompositesandwichbeamswasmuchlessthanthatofconcreteandsteel,withdensitiesof2400kg/m3and7850kg/m3respectively.

Table1summariestheultimatestrengthandYoung'smodulusoftheGFRPface-skins,lattice-webs,andcorematerials.

Table1.

Effectivemechanicalpropertiesoftheglassfiberskinsandcorematerials.

PropertiesSkinsandwebsPaulowniawoodSouthernpinewoodCompressionUltimatestrength(MPa)223.

7426.

5332.

76Young'smodulus(GPa)16.

011.

863.

57TensionUltimatestrength(MPa)305.

00——Young'smodulus(GPa)20.

95——ShearUltimatestrength(MPa)16.

273.

346.

55Young'smodulus(GPa)7.

680.

420.

68Twentysandwichbeamswithidenticaldimensions(1400mm*120mm*120mm),including2woodenbeams,2compositesandwichbeamswithoutlattice-webs,and16sandwichbeamswithlattice-webs,werefabricatedandmanufacturedintheAdvancedCompositeStructuresResearchInstituteatNanjingTechUniversity.

DetailsofeachspecimenaresummarizedinTable2.

Horizontallattice-websVerticallattice-websAPFIS2017-6thAsia-PacificConferenceonFRPinStructuresSingapore,19-21stJuly20173HaiFang,HuiyuanShi,WeiqingLiu,YujunQi,andRuiliHuoTable2.

Descriptionofspecimens.

SpecimensSizeofspecimenSizeofcoreOrientationoftestingl(mm)B(mm)H(mm)b(mm)h(mm)PA/SP-CON-F/S1400120120120120FlatwiseandsidewisePA/SP-0-F/S1400120120110110FlatwiseandsidewisePA/SP-1-F140012012011053.

0FlatwisePA/SP-2-F140012012011034.

0FlatwisePA/SP-3-F140012012011024.

5FlatwisePA/SP-4-F140012012011018.

8FlatwisePA/SP-1-S140012012053.

0110SidewisePA/SP-2-S140012012034.

0110SidewisePA/SP-3-S140012012024.

5110SidewisePA/SP-4-S140012012018.

8110Sidewise2.

2.

TestSet-upandInstrumentationThespecimenswereloadedunderstaticfour-pointbendinginaccordancewiththeASTMC393standard[2]byauniversaltestingmachine.

Theloadingexperimentalsetupemployedinthetestswassimplysupportedandthenetspanwas1200mmbetweenthetworollersupports.

Averticalmonotonicloadingwassetbya300kNcapacityhydraulicjack,whichwasequallysplituptotwocentralpointsonthespecimensbyasteeltransferbeamandmovedataloadingrateof2mm/min,asshowninFigure2.

Duringtesting,straincollectionwasperformedbyaDH3816staticstraintestsystem.

TheverticaldisplacementwasmeasuredbyaLVDT(linearvariabledeflectiontransducer)arrangedatthebottomofmid-spanandthetopofsupport.

Twolongitudinalstraingaugestoobservetherelationoftheloadandthestrainoftheface-skinwereattachedtothetopandbottomface-skinsofthemid-span.

Figure2.

Experimentalsetupofflexuralbehaviorofthebeam:(a)pictureofflexuraltestsetup,(b)schematicplot,and(c)straingaugearrangement.

3.

ExperimentalResultsandDiscussionControlspecimensPA-CON-F/SandSP-CON-F/Sfailedinabrittlemanner,asshowninFigure3a.

Theappearanceofsheartensilecrackswasfirstobserved.

Owingtothemaximumshearstrainofthewoodexceedsitscrushingstrain,thesecracks,thatsuddenlyproducedaloudnoise,rapidlyextendedupwardandcausedimmediatefailurewiththeincreaseofslowloadandquickdeflection.

InthecompositesandwichspecimensPA-0-F/SandSP-0-F/S,withoutlatticewebs,brittlefailuredidnotoccurbecausethefibercompositeexternalskinsonthetensilefaceofthespecimensbridgedthecrackedcorecomponentstogethertopreventfailure.

Whenthemaximumcompressivestrainoftheexternalsurfaceexceededitscompressivestrain,toplocalindentationoccurredaswellascompressivecracksonthelateralface-skin,asshowninFigure3b.

Specimenswith1,2,3,and4websintheAPFIS2017-6thAsia-PacificConferenceonFRPinStructuresSingapore,19-21stJuly20174HaiFang,HuiyuanShi,WeiqingLiu,YujunQi,andRuiliHuoflatwisepositionsmainlyfailedbycrushingofthefibercompositeskinsattheloadingpointfollowedbytheoccurrenceofsplittingofthebottomglassfibercausedbyalargedeformationatthebottomofthebeam,asshowninFigure3c.

Compressivewrinklingwasobservedinthesidewisepositions,asshowninFigure3d,andcontinuousapplicationofloadcausedcrackspreadingextendingfromtheuppermosttotheundersection,followedbycompressivefailure.

(a)(b)(c)(d)Figure3.

FailuremodesofGFRP-woodsandwichbeams.

Fromtheexperimentaldataitcanbeseenthattheload-deflectionbehaviorofthespecimenschangesfromlineartononlinearwiththeincreaseinappliedload.

AsshowninFigure4aand4b,whenthecoreisPaulownia,theultimatebendingstrengthofspecimensPA-(1~4)-SisbasicallygreaterthanthatofspecimensPA-(1~4)-F,amongwhichPA-3isthemostobvious.

ThesetrendsinFigure4cand4dcanalsobefoundwithsouthernpinecore.

Meanwhile,theultimatebearingcapacityofthebeamswithsouthernpinewoodisslighterhigherthanthatofbeamswithPaulownia.

Itcanbeconcludedthattheuseofverticalwebsandtheapplicationofhigh-strengthcorematerialwillobtaingreaterbendingstiffnessofthebeam.

(a)(b)(c)(d)Figure4.

Load-deflectioncurvesforsandwichbeam.

4.

ConclusionsInvestigationoftheflexuralbehaviorofinnovativecompositesandwichbeamsreinforcedbylattice-websunderfour-pointstaticbendingtestintheflatwiseandsidewisepositionswasundertakenexperimentallyinthispaper.

WiththisstudyoftheseGFRPsandwichbeams,onegoalistomaximallyincreasethevalueofthesespecimens;theothergoalistoseekastructuretosubstitutefortraditionalbeamsthatwereeasilysubjecttobrittlefailureanddelamination.

Itwasfoundthat,toimprovethecapacityofstiffness,strength,andmonolithicstability,settingupappropriatelaminationandorientationofthelatticewebsforthesandwichbeamsisnecessary.

TheapplicationoffiberinsertionswasfoundtobeviableinthereinforcementandrecoveryofGFRP-woodbeams.

Thistechniqueisnotonlyeasybutalsoconfersgreaterstrengthandstiffnessofreinforcedstructuralelements.

Italsorendersthesystemmorereliable,reducingthepossibilityoftensilefailurecausedbydefects.

APFIS2017-6thAsia-PacificConferenceonFRPinStructuresSingapore,19-21stJuly20175HaiFang,HuiyuanShi,WeiqingLiu,YujunQi,andRuiliHuoAcknowledgmentsTheresearchdescribedherewassupportedbytheNationalNaturalScienceFoundationofChina(GrantNo.

51578285)andfundedbythePriorityAcademicProgramDevelopmentofJiangsuHigherEducationInstitutionsPAPD(GrantNo.

CE02-1-11).

References[1]ZamanA,GutubSA,WafaMA.

AreviewonFRPcompositesapplicationsanddurabilityconcernsintheconstructionsector.

JReinfPlastCompos,2013,32(24):1966-1988.

[2]ASTMC393/C393M-16,Standardtestmethodforcoreshearpropertiesofsandwichconstructionsbybeamflexure,ASTMInternational,WestConshohocken,PA,2016.

edu.

cn,WebPage:http://cce.

njtech.

edu.

cn/view.

aspid=527&class=2212SchoolofCivilEngineering,SoutheastUniversity,Nanjing,ChinaEmail:hyshiseu@yeah.

net3AdvancedEngineeringCompositesResearchCenter,NanjingTechUniversity,Nanjing,ChinaEmail:wqliu@njtech.

edu.

cn,WebPage:http://cce.

njtech.

edu.

cn/view.

aspid=485&class=2404CollegeofCivilEngineering,NanjingTechUniversity,Nanjing,ChinaEmail:qiyujun11@163.

com,WebPage:http://cce.

njtech.

edu.

cn/view.

aspid=1385&class=2215CollegeofCivilEngineering,NanjingTechUniversity,Nanjing,ChinaEmail:ruilihuo@njtech.

edu.

cnKeywords:GFRP-woodsandwichbeams,lattice-webreinforced,flexural,flatwise,sidewiseAbstractThispaperinvestigatestheflexuralbehaviorinflatwiseandsidewisepositionsofnovelgenerationcompositesandwichbeamswithPaulowniaandsouthernpinewoodcoreandglass-fiberreinforcedpolymer(GFRP)facesheetandlattice-webs.

Avacuumassistedresininfusionprocess(VARI)wasemployedtoformsandwichbeamswithdifferentnumbersofwebs.

Twocontrolwoodenbeamsandeighteenlattice-webreinforcedsandwichbeamsweresubjectedtofour-pointbendingteststodeterminetheirstiffness,capacity,andfailuremechanismsintheflatwiseandsidewisepositions.

Theexperimentalresultsrevealedthatthecompositesandwichbeamsfailedinflatwisebendingtestsunderlowerloadbutproducedagreaterdeflectioncomparedtothebeamsinsidewisebendingtests.

Withtheincreaseinthenumberoflattice-webs,ductilitywasfoundtoincreaseinflatwisepositionswhiledecreasinginsidewisepositions.

Analyticalformulasforcalculatingthebendingstiffness,capacity,andductilityoftheGFRP-woodsandwichbeamswereprovided,andtheanalysisresultsformechanicalperformanceshowedgoodagreementwiththeexperimentalresults.

1.

IntroductionComparedtotraditionalconstructionmaterials,themainbenefitsofGFRPcompositematerialinstructuralcomponentsareitshighstrength,excellentcorrosionresistance,easeofhandingandapplication,andflexibilityofdesign[1].

Inthispaperwepresentanewgenerationofcompositesandwichbeamsintendedforuseasloading-bearingcomponents.

Thecompositesandwichisintegrallyformedinthemoldbyavacuum-assistedresininfusionprocessinvolvingcompositeface-skins,webs,andcorematerials,asshowninFigure1.

Onenovelfeatureisthebundlingofthecorematerials,mainlycharacterizedbyhighstrength,intoinbothwebs.

Thesandwichbeams,thatclearlyenhancetheantistrippingandcooperativeperformancebetweensurfacelayerandcore,areconstructedbycloselywrappingwoodcorematerialstogetherusinglattice-websandface-skinsthatcangivefullplaytothepropertiesofthebendingandshearcapacityofthesandwichbeams.

Whenthesurfacelayerofthecompositesandwichbeamisundernormalload,themainfunctionofthewoodcoreistoimproveshapingandbearingandtoprovideelasticsupportsforthesandwichbeams.

Thecompositesandwichbeamavoidstheoccurrenceoflocalbucklinganddebonding,becausethecorematerialimprovesthedistributionofsectionstress,APFIS2017-6thAsia-PacificConferenceonFRPinStructuresSingapore,19-21stJuly20172HaiFang,HuiyuanShi,WeiqingLiu,YujunQi,andRuiliHuoeffectivelyreducingthestressconcentrationattheintersectionofthesurfacelayerandlattice-webs,significantlydelayingsplittingfailure.

Meanwhile,theGFRPlattice-webscaneffectivelyincreasethecapacityofshear,compression,andstripping,bothintheflatwise(horizontal)orinthesidewise(vertical)position.

Inthispaper,theultimatefailuremechanisms,initialbendingstiffness,load-deflectionbehaviorandstress-strainbehaviorofGFRP-woodsandwichbeamsunderfour-pointstaticbendingintheflatwiseandsidewisepositionsarereportedanddiscussed.

Thetheoreticaloutcomesforthestiffnessandstrengthofthecompositesandwichbeamsarealsopredictedandcomparedwiththeexperimentalresults.

(a)(b)(c)Figure1.

Lattice-webreinforcedcompositesandwichbeams(a)flatwise,(b)sidewise,and(c)cross-sectionalviewofrealobject.

2.

ExperimentalProgram2.

1.

TestSpecimensandMaterialsThestructuralsandwichbeamstestedinthisstudywereemployedusingGFRPskinsandlattice-webscomposedofbi-axial[0/90]glassfiberlaminates(800g/m2)andHS-2101-G100unsaturatedpolyesterresintowrapthecorematerialstogether.

High-classPaulowniaorsouthernpinewood,weighing280kg/m3and500kg/m3respectively,werefilledascorematerialsinthesespecimens.

Theoveralldensityofthecompositesandwichbeamswasmuchlessthanthatofconcreteandsteel,withdensitiesof2400kg/m3and7850kg/m3respectively.

Table1summariestheultimatestrengthandYoung'smodulusoftheGFRPface-skins,lattice-webs,andcorematerials.

Table1.

Effectivemechanicalpropertiesoftheglassfiberskinsandcorematerials.

PropertiesSkinsandwebsPaulowniawoodSouthernpinewoodCompressionUltimatestrength(MPa)223.

7426.

5332.

76Young'smodulus(GPa)16.

011.

863.

57TensionUltimatestrength(MPa)305.

00——Young'smodulus(GPa)20.

95——ShearUltimatestrength(MPa)16.

273.

346.

55Young'smodulus(GPa)7.

680.

420.

68Twentysandwichbeamswithidenticaldimensions(1400mm*120mm*120mm),including2woodenbeams,2compositesandwichbeamswithoutlattice-webs,and16sandwichbeamswithlattice-webs,werefabricatedandmanufacturedintheAdvancedCompositeStructuresResearchInstituteatNanjingTechUniversity.

DetailsofeachspecimenaresummarizedinTable2.

Horizontallattice-websVerticallattice-websAPFIS2017-6thAsia-PacificConferenceonFRPinStructuresSingapore,19-21stJuly20173HaiFang,HuiyuanShi,WeiqingLiu,YujunQi,andRuiliHuoTable2.

Descriptionofspecimens.

SpecimensSizeofspecimenSizeofcoreOrientationoftestingl(mm)B(mm)H(mm)b(mm)h(mm)PA/SP-CON-F/S1400120120120120FlatwiseandsidewisePA/SP-0-F/S1400120120110110FlatwiseandsidewisePA/SP-1-F140012012011053.

0FlatwisePA/SP-2-F140012012011034.

0FlatwisePA/SP-3-F140012012011024.

5FlatwisePA/SP-4-F140012012011018.

8FlatwisePA/SP-1-S140012012053.

0110SidewisePA/SP-2-S140012012034.

0110SidewisePA/SP-3-S140012012024.

5110SidewisePA/SP-4-S140012012018.

8110Sidewise2.

2.

TestSet-upandInstrumentationThespecimenswereloadedunderstaticfour-pointbendinginaccordancewiththeASTMC393standard[2]byauniversaltestingmachine.

Theloadingexperimentalsetupemployedinthetestswassimplysupportedandthenetspanwas1200mmbetweenthetworollersupports.

Averticalmonotonicloadingwassetbya300kNcapacityhydraulicjack,whichwasequallysplituptotwocentralpointsonthespecimensbyasteeltransferbeamandmovedataloadingrateof2mm/min,asshowninFigure2.

Duringtesting,straincollectionwasperformedbyaDH3816staticstraintestsystem.

TheverticaldisplacementwasmeasuredbyaLVDT(linearvariabledeflectiontransducer)arrangedatthebottomofmid-spanandthetopofsupport.

Twolongitudinalstraingaugestoobservetherelationoftheloadandthestrainoftheface-skinwereattachedtothetopandbottomface-skinsofthemid-span.

Figure2.

Experimentalsetupofflexuralbehaviorofthebeam:(a)pictureofflexuraltestsetup,(b)schematicplot,and(c)straingaugearrangement.

3.

ExperimentalResultsandDiscussionControlspecimensPA-CON-F/SandSP-CON-F/Sfailedinabrittlemanner,asshowninFigure3a.

Theappearanceofsheartensilecrackswasfirstobserved.

Owingtothemaximumshearstrainofthewoodexceedsitscrushingstrain,thesecracks,thatsuddenlyproducedaloudnoise,rapidlyextendedupwardandcausedimmediatefailurewiththeincreaseofslowloadandquickdeflection.

InthecompositesandwichspecimensPA-0-F/SandSP-0-F/S,withoutlatticewebs,brittlefailuredidnotoccurbecausethefibercompositeexternalskinsonthetensilefaceofthespecimensbridgedthecrackedcorecomponentstogethertopreventfailure.

Whenthemaximumcompressivestrainoftheexternalsurfaceexceededitscompressivestrain,toplocalindentationoccurredaswellascompressivecracksonthelateralface-skin,asshowninFigure3b.

Specimenswith1,2,3,and4websintheAPFIS2017-6thAsia-PacificConferenceonFRPinStructuresSingapore,19-21stJuly20174HaiFang,HuiyuanShi,WeiqingLiu,YujunQi,andRuiliHuoflatwisepositionsmainlyfailedbycrushingofthefibercompositeskinsattheloadingpointfollowedbytheoccurrenceofsplittingofthebottomglassfibercausedbyalargedeformationatthebottomofthebeam,asshowninFigure3c.

Compressivewrinklingwasobservedinthesidewisepositions,asshowninFigure3d,andcontinuousapplicationofloadcausedcrackspreadingextendingfromtheuppermosttotheundersection,followedbycompressivefailure.

(a)(b)(c)(d)Figure3.

FailuremodesofGFRP-woodsandwichbeams.

Fromtheexperimentaldataitcanbeseenthattheload-deflectionbehaviorofthespecimenschangesfromlineartononlinearwiththeincreaseinappliedload.

AsshowninFigure4aand4b,whenthecoreisPaulownia,theultimatebendingstrengthofspecimensPA-(1~4)-SisbasicallygreaterthanthatofspecimensPA-(1~4)-F,amongwhichPA-3isthemostobvious.

ThesetrendsinFigure4cand4dcanalsobefoundwithsouthernpinecore.

Meanwhile,theultimatebearingcapacityofthebeamswithsouthernpinewoodisslighterhigherthanthatofbeamswithPaulownia.

Itcanbeconcludedthattheuseofverticalwebsandtheapplicationofhigh-strengthcorematerialwillobtaingreaterbendingstiffnessofthebeam.

(a)(b)(c)(d)Figure4.

Load-deflectioncurvesforsandwichbeam.

4.

ConclusionsInvestigationoftheflexuralbehaviorofinnovativecompositesandwichbeamsreinforcedbylattice-websunderfour-pointstaticbendingtestintheflatwiseandsidewisepositionswasundertakenexperimentallyinthispaper.

WiththisstudyoftheseGFRPsandwichbeams,onegoalistomaximallyincreasethevalueofthesespecimens;theothergoalistoseekastructuretosubstitutefortraditionalbeamsthatwereeasilysubjecttobrittlefailureanddelamination.

Itwasfoundthat,toimprovethecapacityofstiffness,strength,andmonolithicstability,settingupappropriatelaminationandorientationofthelatticewebsforthesandwichbeamsisnecessary.

TheapplicationoffiberinsertionswasfoundtobeviableinthereinforcementandrecoveryofGFRP-woodbeams.

Thistechniqueisnotonlyeasybutalsoconfersgreaterstrengthandstiffnessofreinforcedstructuralelements.

Italsorendersthesystemmorereliable,reducingthepossibilityoftensilefailurecausedbydefects.

APFIS2017-6thAsia-PacificConferenceonFRPinStructuresSingapore,19-21stJuly20175HaiFang,HuiyuanShi,WeiqingLiu,YujunQi,andRuiliHuoAcknowledgmentsTheresearchdescribedherewassupportedbytheNationalNaturalScienceFoundationofChina(GrantNo.

51578285)andfundedbythePriorityAcademicProgramDevelopmentofJiangsuHigherEducationInstitutionsPAPD(GrantNo.

CE02-1-11).

References[1]ZamanA,GutubSA,WafaMA.

AreviewonFRPcompositesapplicationsanddurabilityconcernsintheconstructionsector.

JReinfPlastCompos,2013,32(24):1966-1988.

[2]ASTMC393/C393M-16,Standardtestmethodforcoreshearpropertiesofsandwichconstructionsbybeamflexure,ASTMInternational,WestConshohocken,PA,2016.

- involving网易yeah相关文档

- 网易网易hr管培生北京笔试试题

- 照片一篇完整的网易笔试题

- 扁豆网易yeah

- 0.21网易yeah

- 戏曲网易yeah

- 3.2网易yeah

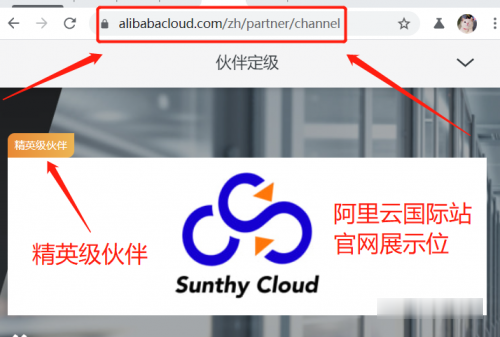

SunthyCloud阿里云国际版分销商注册教程,即可PayPal信用卡分销商服务器

阿里云国际版注册认证教程-免绑卡-免实名买服务器安全、便宜、可靠、良心,支持人民币充值,提供代理折扣简介SunthyCloud成立于2015年,是阿里云国际版正规战略级渠道商,也是阿里云国际版最大的分销商,专业为全球企业客户提供阿里云国际版开户注册、认证、充值等服务,通过SunthyCloud开通阿里云国际版只需要一个邮箱,不需要PayPal信用卡就可以帮你开通、充值、新购、续费阿里云国际版,服务...

星梦云:四川100G高防4H4G10M月付仅60元

星梦云怎么样?星梦云资质齐全,IDC/ISP均有,从星梦云这边租的服务器均可以备案,属于一手资源,高防机柜、大带宽、高防IP业务,一手整C IP段,四川电信,星梦云专注四川高防服务器,成都服务器,雅安服务器。星梦云目前夏日云服务器促销,四川100G高防4H4G10M月付仅60元;西南高防月付特价活动,续费同价,买到就是赚到!点击进入:星梦云官方网站地址1、成都电信年中活动机(成都电信优化线路,封锁...

触碰云高性价20.8元/月,香港云服务器,美国cn2/香港cn2线路,4核4G15M仅115.2元/月起

触碰云怎么样?触碰云是一家成立于2019年的商家。触碰云主营香港/美国 VPS服务器、独立服务器以及免备案CDN。采用的是kvm虚拟构架,硬盘Raid10,Cn2线路,去程电信CN2、移动联通直连,回程三网CN2。最低1核1G带宽1M仅20.8元/月,不过这里推荐香港4核4G15M,香港cn2 gia线路云服务器,仅115.2元/月起,性价比还是不错的。点击进入:触碰云官方网站地址触碰云优惠码:优...

网易yeah为你推荐

-

企业cmscms系统的概念是什么开启javascript怎样手动开启Javascript重庆电信断网重庆电信的最近是怎么回事啊!老断网重庆网站制作我想做个网站,我是重庆的人。想在本地找个做网站的公司,请教一下在重庆那个公司比较好一点,,,,谢谢资费标准联通所有套餐介绍购物车(淘宝)为什么推荐购物车购买,是什么意思啊?银花珠树晓来看晚来天欲雪,能饮一杯无。相似的句子35邮箱邮箱地址怎么写申请400电话申请400电话需要哪些流程?办理哪些证明?网站后台密码破解怎样破解网站后台管理用户名密码