指南FDA指南-药品生产中不合格OOS结果的调查-中英文版

FDAOOS指南

Guidance for Industry

Investigating Out-of-Specification(OOS)Test Results for Pharmaceutical Production药品生产中不合格(OOS)结果的调查

U.S.Department of Health and Human Services

Food and Drug Administration

Center for Drug Evaluation and Research(CDER)

October 2006

Pharmaceutical CGMPs

仅供华润九新内部交流切勿外传

FDA OOS指南 Contains Nonbinding Recommendations包含不具约束力的建议

Guidance for Industry

Investigating Out-of-Specification(OOS)Test Results for Pharmaceutical Production药品生产中不合格(OOS)结果的调查

Additional copies are availablefrom:本文件可自以下途径得到

Ofice of Training and Communication培训和交流办公室

Division ofDrug Information HFD-240药品信息分部

Centerfor Drug Evaluation and Research药品审评中心

Food and Drug Administration食品药品管理局

5600 Fishers Lane

Rockville,MD 20857

(Tel)301-827-4573http://wwwfda gov/cder/guidance/index htm

U.S.Department of Health and Human Services

美国卫生和福利部

Food and Drug Administration

食品药品管理局

Center for Drug Evaluation and Research(CDER)

药品审评中心

October 2006

2006年10月

Pharmaceutical CGMPs

仅供华润九新内部交流切勿外传

FDA OOS指南 Contains Nonbinding Recommendations包含不具约束力的建议

TABLE OF CONTENTS

目录

I. INTRODUCTION简介.......................................................................................4

II. BACKGROUND 背景........................................................................................6

III. IDENTIFYING AND ASSESSING OOS TEST RESULTS—PHASE I:

LABORATORY INVESTIGATION

界定和评价OOS检验结果—第一步:实验室调查............................................8

A.Responsibility of the Analyst检验员职责.....................................................................9

B.Responsibilities of the Laboratory Supervisor实验室主管职责..............................10

IV. INVESTIGATING OOS TEST RESULTS—PHASE II:FULL-SCALE OOS

INVESTIGATION

对OOS检验结果的调查—第二步:全面OOS调查……………………….......13

A.Review of Production生产情况审核...........................................................................14

B.Additional Laboratory Testing附加的实验室检验...................................................15

C.Reporting Testing Results报告检验结果...................................................................18

V. CONCLUDING THE INVESTIGATION调查结论......................................24

A.Interpretation of Investigation Results调查结果解读..............................................24

B.Cautions注意事项........................................................................................................26

C.Field Alert Reports区域警惕性报告..........................................................................27

仅供华润九新内部交流切勿外传

FDA OOS指南 Contains Nonbinding Recommendations包含不具约束力的建议

1

GUIDANCE FOR INDUSTRY

1

行业指南

Investigating Out-of-Specification(OOS)Test Results for

Pharmaceutical Production

药品生产中不合格结果(OOS)的调查

I. INTRODUCTION简介

This guidance for industry provides the Agency’s current thinking on how to evaluateout-of-specification(OOS) test results.For purposes of this document, the term OOSresults includes all test results that fall outside the specifications or acceptance criteriaestablished in drug applications,drug master files (DMFs),official compendia,or by themanufacturer.The term also applies to all in-process laboratory tests that are outside ofestablished specifications.2

本指南旨在表达当局对如何评估OOS结果的最新想法。本文件中OOS结果这个术语包括所有不符合质量标准或经由药品申请、DMF文件、官方药典及生产商所确立的可接受标准的检测结果。这个术语也适用于所有不符合已建立标准的中控实验室检测结果。 2

Quality in the Center for Drug Evaluation and Research(CDER).

1本指南由药品评审中心CDER生产和产品质量分部法规符合办公室起草。

system adjustments to prevent process drift.This guidance does not address these situations.2在特定情况下 中控检测的目的仅仅是触发实时设备和体系调节以防止工艺偏差。本指南不适用于这种情况。

仅供华润九新内部交流切勿外传

FDA OOS指南 Contains Nonbinding Recommendations包含不具约束力的建议

This guidance applies to chemistry-based laboratory testing of drugs regulated by CDER.It is directed toward traditional drug testing and release methods.These laboratory testsare performed on active pharmaceutical ingredients,excipients and other components,in-process materialsmanufacturing practice(CGMP)regulations (21 CFR parts 210 and 211)and the FederalFood,Drug,and Cosmetic Act (the Act) (section 501(a)(2)(B))apply.The principles inthis guidance also apply to in-house testing of drug product components that arepurchased by a firm.This guidance can also be used by contract firms performingproduction and/or laboratory testing responsibilities.Specifically, the guidance discusseshow to investigate OOS test results, including the responsibilities of laboratory personnel,the laboratory phase of the investigation,additional testing that may be necessary,whento expand the investigation outside the laboratory,and the final evaluation of all testresults.

本指南适用于由CDER管理的药品类别的化学实验室。它直接针对传统的药品检验和放行方法。这些实验室检测项目是对活性药物成份(API)、辅料和其它组分、中控材料和制剂成品3这些就是CGMP法规21 CFR210部分和211部分和联邦食品药品和化妆品法案501(a)(2)(B)所适用的范围。本指南也适用于公司采购的用于制剂成品的组分在公司内的检验。本指南同样能用于承担生产和/或实验室检验的合同公司。尤其是指南讨论如何调查OOS结果时包括实验室人员职责实验室调查阶段、可能需要的附加测试、何时扩大调查至实验室之外和所有检测结果的最终评价。

The Agency, in accordance with its August 2002“Pharmaceutical CGMPs for the 21 stCentury”initiative,encourages modern approaches to manufacturing,monitoring,andcontrol to enhance process predictability and efficiency.Process Analytical Technology(PAT) takes a different approach to quality assurance by using process controls andin-process data as the release specification instead of relying on single laboratorydeterminations to make batch acceptability decisions.This guidance is not intended toaddress PAT approaches,as routine in-process use of these methods might include otherconsiderations.For information on timely in-process testing, see the CGMP guidanceentitled PAT—A Frameworkfor Innovative Pharmaceutical Development,

Manufacturing,and Quality Assurance.

FDA根据2002年8月“21世纪药品的CGMP”管理原则鼓励生产商运用现代的检测与控制技术确保生产过程控制的可预见性与有效性。工艺分析技术(PAT)是采用不同的方法通过过程控制和在线数据的检测而代替单一的实验室检测进行批合格放行的技术。该指南并不打算叙述PAT的方法。如何及时的进行在线检测请看CGMP指南标题是 PAT—创新药品研发、生产和质量保证框架。

are within the scope of this guidance.However, this guidance is not intended to address biologicalassays (e.g., in vivo, immunoassays).

3由CDER负责的生物技术产品的化学检测项目在本指南范围内。但本指南不适用于生物含量检测例如体内免疫检测 。

仅供华润九新内部交流切勿外传

FDA OOS指南 Contains Nonbinding Recommendations包含不具约束力的建议

FDA's guidance documents, including this guidance,do not establish legally enforceableresponsibilities. Instead,guidances describe the Agency's current thinking on a topic andshould be viewed only as recommendations,unless specific regulatory or statutoryrequirements are cited.The use of the word should in Agency guidances means thatsomething is suggested or recommended,but not required.

FDA的指南文件包括本指南并不具备法律上的强制性。 。它仅仅是代表了FDA的目前的想法和推荐的方法应该当作一种推荐来采纳除非在其中引用了特定的法规要求。 FDA指南中出现的“should”指得是建议或推荐并不是强制要求。

II. BACKGROUND背景

Laboratory testing,which is required by the CGMP regulations (§§211.160 and 211.165),is necessary to confirm that components,containers and closures, in-process materials,and finished products conform to specifications, including stability specifications.CGMP法规211章第160部分和211章第165部分要求实验室对药品的成分、容器和密封器材、过程控制及成品进行检测确保其达到既定的标准要求包括稳定性标准要求。Testing also supports analytical and process validation efforts.4 General CGMPregulations covering laboratory operations can be found in part 211, subparts I

(Laboratory Controls)and J(Records and Reports).These regulations provide for theestablishment of scientifically sound and appropriate specifications, standards,and testprocedures that are designed to ensure that components,containers and closures,in-process materials,and finished drug products conform to the established standards.Section 211.165(f)of the CGMP regulations specifies that finished drug products that failto meet established standards, specifications,or other relevant quality control criteria willbe rejected.

检验也应支持方法验证和工艺验证。 4通用CGMP法规包括实验室操作在211部分章节I (实验室控制)和J(记录和报告)可以查阅到。这些法规用于建立科学合理和适当的质量规格、标准和检验方法用于保证组分、容器和密闭器材、 中控材料和制剂成品符合既定标准。CGMP法规211部分165 f指出制剂成品不符合既定标准、规格或其它相应质量控制标准时应拒绝放行。

validated as to their accuracy, sensitivity, specificity,and reproducibility(§211.165(e)),and thesuitability of the test procedures under actual conditions of use must be documented(§211.194(a)(2)).For products that are the subjects of new drug applications (NDAs),abbreviated new drug applications(ANDAs),or investigational new drug applications (INDs), specifications are contained in theapplication or DMF.Specifications for nonapplication products may be found in official compendia orestablished by the manufacturer.

4制订的标准应科学合理并恰当211章第160部分b 检测方法应经过验证验证应包括准确度、灵敏度、专属性及重复性211章165部分e 测试时所做的系统适用性试验数据应记录211章194部分a 2 。对于新药申请NDA 、仿制新药申请ANDA和研究用新药申请IND的药品其质量标准应包括在申报文件或DMF文件中。非申请项目的药品的质量标准应为公定标准或生产厂商自建标准。

仅供华润九新内部交流切勿外传

FDA OOS指南 Contains Nonbinding Recommendations包含不具约束力的建议

Both finished pharmaceuticals and active pharmaceutical ingredients (APIs)are to bemanufactured in accordance with current good manufacturing practice under section.

制剂成品和原料药APIs生产均应符合现行GMP对应条款下的要求。

501(a)(2)(B)of the Act.Current good manufacturing practice for APIs includes theperformance of scientifically sound raw material testing, in-process monitoring,releaseand stability testing,process validation,and adequate investigations of any OOS resultobtained from such testing.All citations to part 211 in this document pertain to finishedpharmaceuticals,but these referenced regulatory requirements are also consistent withAgency guidance on CGMPs for APIs with respect to laboratory controls,which includeout-of-specification investigations.See FDA’s guidance for industry Q7A GoodManufacturing Practice Guidancefor Active Pharmaceutical Ingredients(ICH Q7A)forspecific recommendations.

法规的501(a)(2)(B)中对原料药API的CGMP包括科学合理的原料检测、中控监测、放行和稳定性测试、工艺验证和对任何来自于这些测试的OOS结果的充分的调查。本文中所有对CFR211章的引用都涉及制剂产品但这些相关法规要求也与FDA对原料药实验室控制方面的要求一致其中包括OOS调查。参见FDA行业指南 Q7A活性药物成份(API)良好生产规范指南(GMP) ICH Q7A 。 5

The responsibility of a contract testing laboratory in meeting these requirements isequivalent to that of a manufacturing firm.

对合同实验室的要求与对生产公司的实验室要求相同。

CDER guidance page at http://www fda gov/cder/guidance/index htm

5我们定期更新各指南。为保证使用最新版本的指南请至http://www fda gov/cder/guidance/index htm访问CDER指南页。

仅供华润九新内部交流切勿外传

FDA OOS指南 Contains Nonbinding Recommendations包含不具约束力的建议

III. IDENTIFYING AND ASSESSING OOS TEST RESULTS—PHASE I:

LABORATORY INVESTIGATION

界定和评价OOS检验结果—第一步:实验室调查

FDA regulations require that an investigation be conducted whenever an OOS test resultis obtained(§211.192).6 The purpose of the investigation is to determine the cause of theOOS result.The source of the OOS result should be identified either as an aberration ofthe measurement process or an aberration of the manufacturing process.Even if a batch isrejected based on an OOS result, the investigation is necessary to determine if the result isassociated with other batches of the same drug product or other products.Batch rejectiondoes not negate the need to perform the investigation.The regulations require that awritten record of the investigation be made, including the conclusions and follow-up(§

211.192).

FDA法规要求当发现OOS结果时应立即展开调查6。调查的目的是确定引起OOS的原因。应确定是检验过程的异常还是生产工艺异常导致的OOS结果。即使因OOS结果判定了不合格的批仍必须进行调查以确定该结果是否影响到同种产品其它批号或其它产品一批不合格也不能否定调查的必要。法规(§211.192)要求要有调查的书面记录包括结论和跟进措施。To be meaningful, the investigation should be thorough, timely,unbiased,well-documented,and scientifically sound.The first phase of such an investigation shouldinclude an initial assessment of the accuracy of the laboratory's data.Whenever possible,this should be done before test preparations (including the composite or the homogenoussource of the aliquot tested)are discarded.This way,hypotheses regarding laboratoryerror or instrument malfunctions can be tested using the same test preparations. If thisinitial assessment indicates that no meaningful errors were made in the analytical methodused to arrive at the data,a full-scale OOS investigation should be conducted.Forcontract laboratories, the laboratory should convey its data,findings,and supportingdocumentation to the manufacturing firm’s quality control unit (QCU),who should theninitiate the full-scale OOS investigation.

为了使调查有意义调查应是彻底及时公正详细记录并经得起科学推敲。调查的第一阶段应包括对实验室数据的准确性的初步评价。只要可能在倒掉制备液之前包括被检测液的来源均应进行实验数据的准确性初步评估。这样关于实验室错误或故障仪器的假定就可以通过用相同的溶液检测来论证。如果初步评估显示在得到该数据的分析过程中没有错误应进行全面的OOS调查。如果OOS结果出自合同实验室实验室应将数据、所有发现和支持性文件提交生产企业的质量控制部门(QCU) 以便其展开全面的OOS调查。

that are out of trend

6虽然本文的主题是OOS结果指南内许多内容对于检查偏离趋势结果亦有帮助。

仅供华润九新内部交流切勿外传

FDA OOS指南 Contains Nonbinding Recommendations包含不具约束力的建议

A. Responsibility of the Analyst检验员职责

The first responsibility for achieving accurate laboratory testing results lies with theanalyst who is performing the test.The analyst should be aware of potential problems thatcould occur during the testing process and should watch for problems that could createinaccurate results.

得到精确的检验结果的第一责任人是在进行检验的检验员。检验员应该意识到在实验过程中可能发生的潜在的问题和应该注意可能产生OOS结果的问题。

In accordance with the CGMP regulations in§211.160(b)(4), the analyst should ensurethat only those instruments meeting established performance specifications are used andthat all instruments are properly calibrated.

依据cGMP(§211.160(b)(4))的要求检验员应该确证只有符合标准的仪器才能使用还要确认所有的仪器都经过的校正。

Certain analytical methods have system suitability requirements,and systems not meetingthese requirements should not be used.For example, in chromatographic systems,reference standard solutions may be inj ected at intervals throughout chromatographic runsto measure drift,noise,and repeatability. If reference standard responses indicate that thesystem is not functioning properly,all of the data collected during the suspect time periodshould be properly identified and should not be used.The cause of the malfunction shouldbe identified and, if possible,corrected before a decision is made whether to use any dataprior to the suspect period.

某些分析方法有系统适用性要求系统适应性不符合要求其检测数据就不能使用。例如在色谱系统中在一定的时间间隔内重复进样标准溶液去测定漂移、噪声、重复性。如果标准溶液获得的数据表明系统适用性不符合要求就表明仪器不正常在这段时期内获得的数据即为无效数据。如可能故障原因应该查出并在决定是否采用可疑时间段之前的任何数据前应采取纠正措施。

Analysts should check the data for compliance with test specifications before discardingtest preparations or standard preparations.When unexpected results are obtained and noobvious explanation exists, test preparations should be retained, if stable,and the analystshould inform the supervisor.An assessment of the accuracy of the results should bestarted immediately.

检验员在丢弃供试品溶液和标准溶液前应该检查数据是否符合检测标准。如果出现结果不在预期内且没有明显的解释若供试品溶液稳定则应保留改溶液同时检验员应该通知主管。对结果准确性的评估应立即开始。

仅供华润九新内部交流切勿外传

spinservers:圣何塞10Gbps带宽服务器月付$109起,可升级1Gbps无限流量

spinservers是Majestic Hosting Solutions LLC旗下站点,主营国外服务器租用和Hybrid Dedicated等,数据中心在美国达拉斯和圣何塞机房。目前,商家针对圣何塞部分独立服务器进行促销优惠,使用优惠码后Dual Intel Xeon E5-2650L V3(24核48线程)+64GB内存服务器每月仅109美元起,提供10Gbps端口带宽,可以升级至1Gbp...

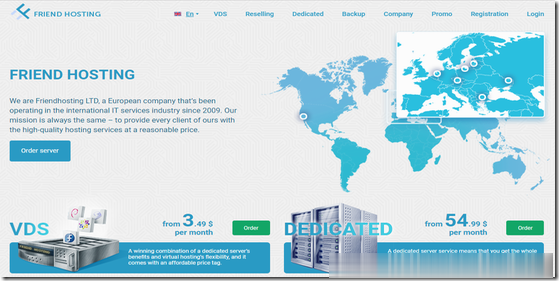

Friendhosting全场VDS主机45折,虚拟主机4折,老用户续费9折

Friendhosting发布了今年黑色星期五促销活动,针对全场VDS主机提供45折优惠码,虚拟主机4折,老用户续费可获9折加送1个月使用时长,优惠后VDS最低仅€14.53/年起,商家支持PayPal、信用卡、支付宝等付款方式。这是一家成立于2009年的老牌保加利亚主机商,提供的产品包括虚拟主机、VPS/VDS和独立服务器租用等,数据中心可选美国、保加利亚、乌克兰、荷兰、拉脱维亚、捷克、瑞士和波...

香港服务器租用多少钱一个月?影响香港服务器租用价格因素

香港服务器租用多少钱一个月?香港服务器受到很多朋友的青睐,其中免备案成为其特色之一。很多用户想了解香港云服务器价格多少钱,也有同行询问香港服务器的租赁价格,一些实际用户想要了解香港服务器的市场。虽然价格是关注的焦点,但价格并不是香港服务器的全部选择。今天小编介绍了一些影响香港服务器租赁价格的因素,以及在香港租一个月的服务器要花多少钱。影响香港服务器租赁价格的因素:1.香港机房选择香港机房相当于选择...

-

推广方法营业推广的方式有哪些行业关键词关键词有哪些分类?iphone5解锁iphone5密码忘了怎么解锁vista系统重装vista怎样重装系统?工信部备案去国家工信部备案需要什么手续呢安卓应用平台安卓系统支持的软件并不是那么多,为什么这么多人推崇?申请证书求高手教下怎么申请证书ios系统ios是什么意思 ios系统是什么电子商务网站模板电子商务网站模板哪个好?电子商务网站模板免费建站怎么样?系统分析员系统分析员的工作内容