correctedcornerradius

cornerradius 时间:2021-02-18 阅读:()

Chapter9.

FiveAxisToolPathGenerationMethodsOptimizedNC-toolpathgenerationfor5-axismachiningofcomplexsurfacesProf.

Dr.

Ir.

I-P.

Kruth(Jean-Pierre.

Kruth@mech.

kuleuven.

ac.

be)KatholiekeUniversiteitLeuven,Celestijnenlaan300B,3001Heverlee,BelgiumProf.

Dr.

Ir.

B.

Lauwers,IrP.

DejongheandIr.

1.

DotremontKatholiekeUniversiteitLeuven,Celestijnenlaan300B,3001Heverlee,BelgiumKeywords:CAD/cAM,5-axismillingAbstract:Thetoolpathgenerationmethoddescribedinthispaperisenhancingthesculpturedsurfacemachiningmethods,whichcanbefoundincommercialCAM-softwarepackages.

Toolaxisinclinationoptimizationisdonebasedonthepropertiesoftheunderlyingsurfaceandisaguaranteeforgouge-freeNC-toolpaths.

Thetoolinclinationvariesalongthetoolpathinsuchawaythattoolinclinationisoptimizedforeachindividualtoolposition.

TheproposedmethodusesprojecteddrivepatternsandisabletotakecareofmUltipleandeventrimmedpartsurfaces.

1.

INTRODUCTIONFiveaxismachiningoffreeformsurfaceshasmanyadvantagesifcylindricalortoricalcuttersareusedinsteadofballnosecutters.

Comparedtotraditionalthreeaxismachining,thematerialremovalrateincreasesandthemachiningtimereduces.

CommercialCAM-systemswithmulti-axiscapabilityareforcingtheoperatortogivethetoolacertainconstantleadand/ortiltangle(1)withrespecttothesurfacenormal.

Furtherasetofmultipleandtrimmedsurfacescanbemachinedwithinoneoperationthroughtheuseofdrivesurfaces.

Thedrivesurfaceisusedtogeneratetrajectoriesinacontactdrivenway,whicharethenprojectedontothepartsurfaces.

Thetoolorientationiscalculatedbasedeitheronthedrivesurfaceorthepartsurface.

Smallleadanglesarefavourabletothematerialremovalrate,surfaceroughnessandsurfaceaccuracy[2].

But,applyingasmallconstantleadanglealongthemillingpathcancausedifferentproblemslikegougingandvariationsinthescallopheight.

Asasolutionforthis,severalresearchershaveinvestigatedthedynamicoptimizationandadaptationofthetoolinclinationalongthetooltrajectory[1][2].

Themaindrawbackofmostofthesemethodsisthattheyarecontactdriven.

Thismeansthatthetoolisguidedalongtheisoparametriclinesofthepartsurface.

Asaresult,onlysinglesurfaceswithouttrimmingscanbemachined.

Thetoolpathgenerationmethoddescribedinthispaperoptimizesthetoolinclinationineachpointofthepartsurface.

ThesedevelopmentsfitintheframeoftheOPTIMACHproject.

ThegoalsofthisEU-fundedprojectare:Createreliablecollision-anderror-freeNC-programsthroughanon-lineclosedloopsimulationsystem.

Enhancemillingstrategiesinordertoimprovetheachievedsurfacequalitythroughoptimizingthetoolanglew.

r.

t.

theworkpieceandthestep-over.

Theoriginalversionofthischapterwasrevised:Thecopyrightlinewasincorrect.

Thishasbeencorrected.

TheErratumtothischapterisavailableatDOI:IFIPInternationalFederationforInformationProcessing199910.

1007/978-0-387-35392-0_40G.

J.

Ollingetal.

(eds.

),MachiningImpossibleShapesDependingontheprerequIsItesposedbytheusedCAD/CAMsystem,twomainapproacheshavebeenfollowedduringthedevelopment.

Thefirstapproachisbasedontheprototypesoftware,whichhasbeendevelopedinthepastatthedivisionPMAoftheK.

U.

Leuven[2].

Thesecondapproachisamorepracticalsolution,takingawaythedisadvantagesfromthefirstone.

Inbothcases,theinclinationadjustmentisdoneduringthetoolpathgenerationstep(greycolouredblockonFigure1)andnotduringNC-simulation,NC-verificationoronthemachine.

'"Loadll,20-'IFedral,200GOlDx,Y,z,i,j,k,Col/sonme$$llgeIN1T20M6IN2G1X,.

Y.

.

Z.

.

B.

.

C.

.

F300\.

jFigure1.

Overviewofthetoolpathgenerationprocessfora5-axisNC-program2.

FIRSTAPPROACH:NUMERICALOPTIMIZATIONBASEDONTHEANALYTICREPRESENTATIONOFTHEWORKPIECEGEOMETRY.

Forthisfirstapproach,thestandardCAD/CAM-routinesareusedtocalculateeachtoolposture.

Atoolpostureisthecombinationoftoolposition(xyz)andtoolorientation(ijk).

ThetoolinclinationascalculatedbytheCAD/CAM-systemisthenusedasthestartingvaluefortheoptimizationalgorithms.

TheroutinesofthestandardCAD/CAM-systemaregeneratingthetoolposturesinthefollowingmanner(Figure2):,A"".

.

/i)////.

/,///'//gJPSFigure2.

Methodforgeneratingtoolpostures344osAcertaininclinationangleisappliedtothetoolW.

r.

t.

thesurfacenormalofthecorrespondingtooltippointinthepartsurface.

Thetoolisthenprojectedontothepartsurface,whereacontactpoint(CP)isfound.

lftheinclinationangleappliedtothetoolislargeenough,thecontactpointwilllieinfrontofthecutter.

Theoptimizationalgorithm,explainedhereforacylindricalcutter,calculatesthemaximalangleoverwhichthecuttermayberotatedaroundthecontactpoint(CP)tofitascloseaspossibletothepartsurface.

Todothis,thealgorithmconstructsafunction8=f(u,v)representingtherelationshipbetweentheunderlyingsurfaceofthetoolandtheangleoverwhichthecutterisallowedtorotate.

ThisfunctionisthenminimizedtoobtaintheangleTheminimizationprocedureisbasedonatwo-dimensionalNewton-Raphsonmethodstartingfromagivenpointonthepartsurface.

Theresultofthisminimizationmethodisthenearestlocaloptimuminthesurroundingofthegivenpoint.

Figure3.

ElementarydiscinsidethecutterThesizeoftheunderlyingsurfaceforwhichthefunction8=f(u,v)isdefined,isdirectlyrelatedtothetooldiameter.

Thechanceforhavingmorelocalminimaincreaseswiththesizeofthecutter.

Asaconsequence,theanglehastobecalculatedformorethanonepoint,tobesuretofindthesmallestone.

Thisisdonebychoosinganumberofpointsonthebottomofthecylindricalcutter.

Foreachpoint,thefollowingisexecuted:1)Computetheshortestdistancetotheunderlyingpartsurface.

Consequently,thenearestpoint(PI)onthepartsurfaceisfound.

2)Theminimizationisof8=f(u,v)isdonestartingfromthepointPI.

3)Repeatstep2untiltherequestedaccuracyisachieved.

s:;pCPworlDCP_.

.

_.

.

_.

.

_.

.

_.

.

-··'1Z··_.

.

-,:/.

/OSPSThefulltoolwiththeestimatedtoolaxisisprojecteddownonthesurface.

ThisisdonebyusingthestandardCAD/CAMsystems'functionalityfortoolprojection.

Thetoolprojectionreturnsacontactpoint(UCP),whichmightactuallybeinglocatedeverywhereonthebottomofthecutter.

Thetoolaxisisthenac(justed(acertainvalueisaddedforB),basedontherelationshipbetweenthecontactpoint(CP)andthecontactpointreturnedbythetoolprojectionmethodUCP.

TheoalistoetCPascloseasossibletoUCP.

347PSThetoolisprojectedagainwiththenewlyfoundtoolaxis.

Doingthetoolprojectioneverytime,gougingisavoided.

Stepse,0andf)arerepeateduntilacertaincriterionisfulfilled.

Possiblecriterionsare,'UCPcloseenouhtoCP,iJ.

8notositiveanmore,.

.

.

Ingeneral,after2or3iterationstheoptimizedtoolpostureisfound.

Greatcareistakentonotrushthetoolaxisvariations.

Fastdecreasesofthetoolinclinationangle{)cancausethecuttertocutwithhisback.

Thisisnotfavourablefortoolsthatdonotcutwiththecentre(e.

g.

toricalcutters).

Quicklyincreasingthetoolinclinationontheotherhandcanhelpthecuttertoavoidgouging.

Asaresult,thedisturbanceofthetoolinclinationangle{)perdistanceunitislimitedtodifferentvaluesfordecreasingandincreasingtoolaxisinclinationvalues.

4.

\MACHININGRESULTSFortheexperimentalverificationoftheappliedmethod,aworkpiece(dimensions100x100mm)withaconcaveandconvexregion(Figure6)wasmilledoutofureolandaluminiumusingafive-axisMAHO600Cmillingmachine.

Duringtheexperiments,atoricalcutterwithadiameterof20mmandacornerradiusof4mmwasused.

Thenumberoftracksalwaysequalsto20.

ZCIYCFigure6.

Surfacewithconvexandconcaveregion348OneworkpiecewasmilledwiththestandardroutinesoftheCAD/CAM-system.

Forthistest,aminimalinclinationangleof9degreeshasbeenapplied.

Anotherworkpiecewasmilledusingtheoptimizedtoolaxisinclinationroutines.

Thescallopheightofthetwoworkpieceswasinvestigatedusinga3DcoordinatemeasuringmachineCOORD3equippedwithaWolf&Becklaser-scanningprobe.

Figure7showstherawscanningdata.

·202040608J100120·1·2·3Figure7.

Measuredprofileoftheworkpieceintheconvexregion.

Forthisspecificcase,thelargestbenefitoftheoptimizedmethodcomparedwiththestandardmethodwasfoundintheconvexregion.

Intheconcaveregionthecutterwillalwaysbeforcedtoalargertoolinclinationinordertopreventgouging.

5.

CONCLUSION&CONTINUATIONOFWORKTheproposedalgorithmshavebeenimplementedinsideacommercialCAD/CAMsystem.

Experimentsprovethealgorithmsfromthesecondapproachtoberobustandgeneralapplicable.

Sincetheoptimizationofthetoolpostureresultsinalargermaterialremovalrateandasmallerscallop,theneedforanaccuratestep-overcalculationalgorithmisoriginating.

ACKNOWLEDGEMENTSTheOPTIMACHprojectisbeingcarriedoutintheframeoftheIndustrialandMaterialsTechnologiesresearchandtechnologicaldevelopmentprogrammeoftheEuropeanCommunitywithafinancialECcontributionupto1.

923kECU.

MoreinformationaboutthisprojectcanbefoundontheOPTIMACH-webpages:APPENDIXDifferentangularsystemsareinusetodefinethetoolaxisinclination.

Themostpopularsystem,whichalsoisfoundinmostcommercialCAM-systemsisthelead-tiltsystem349(Figure8).

However,theinclination-screwsystemhasadvantagesinthewaythecalculationsaredone,butislessobviousfortheuseroftheCAM-system.

normalvectorZznormalvectortoolcenterpoint0toolcenterpoint0ycpfeeddirectionfeeddirectionFigure8.

Thelead-tiltsystem(lead=aandtilt=P)versustheinclination-screwsystem(inclination=eandscrew=(j).

Theabilityexiststoswitchfromoneangularsystemtoanotherusingtheseformulas:Table1.

TransistionformulasbetweenbothangularsystemsXinclination-screw=cosrp.

sin()X'ead-tilt=smaYinclination-screw=sinrp.

sin()Ylead-tilt=-cosa.

sinf3Zinclinalion-screw=cos()Zlead-tilt=cosa.

cosf3REFERENCES[I]ChoiB.

K.

,ParkJ.

W.

,JunC.

S.

,Cutter-locationdataoptimizationin5-axissurfacemachining,ComputerAidedDesign,vol.

25,no.

6,1993.

y[2]KruthJ.

-P.

,KlewaisP.

,OptimizationandDynamicAdaptationoftheCutterInclinationduringFive-AxisMillingofSculpturedSurfaces,AnnalsoftheCIRP,vol.

43/1,p.

443-448,1994[3]LeeY.

S.

,DecisionSupportEnvironmentforAdvancedMulti-axisCNCMachining,4thIndustrialEngineeringResearchConferenceProceedings,p.

260-268,1995.

[4]LeeY.

S.

,JiH.

,Surfaceinterrogationandmachiningstripevaluationfor5-axisCNCdieandmoldmachining,InternationalJournalofProductionResearch,vol.

35,no.

1,p.

22-252,1995[5]LiS.

X.

,JerardR.

B.

,5-axismachiningofsculpturedsurfaceswithaflat-endcutter,ComputerAidedDesign,vol.

26,no.

3,1994.

[6]MarciniakK.

,GeometricModellingforNumericallyControlledMachining,OxfordUniversityPress,1991.

[7]MarciniakK.

,Influenceofsurfaceshapeonadmissibletoolpositionsin5-axisfacemilling,ComputerAidedDesign,vol.

19,no.

5,1987.

[8]SaarA.

,LauwersB.

,DejongheP.

,Optimisedtoolpathgenerationmethodsforeconomicandcollisionfreemulti-axismachining,Proceedingofthe31stISATAconference,1998.

350

FiveAxisToolPathGenerationMethodsOptimizedNC-toolpathgenerationfor5-axismachiningofcomplexsurfacesProf.

Dr.

Ir.

I-P.

Kruth(Jean-Pierre.

Kruth@mech.

kuleuven.

ac.

be)KatholiekeUniversiteitLeuven,Celestijnenlaan300B,3001Heverlee,BelgiumProf.

Dr.

Ir.

B.

Lauwers,IrP.

DejongheandIr.

1.

DotremontKatholiekeUniversiteitLeuven,Celestijnenlaan300B,3001Heverlee,BelgiumKeywords:CAD/cAM,5-axismillingAbstract:Thetoolpathgenerationmethoddescribedinthispaperisenhancingthesculpturedsurfacemachiningmethods,whichcanbefoundincommercialCAM-softwarepackages.

Toolaxisinclinationoptimizationisdonebasedonthepropertiesoftheunderlyingsurfaceandisaguaranteeforgouge-freeNC-toolpaths.

Thetoolinclinationvariesalongthetoolpathinsuchawaythattoolinclinationisoptimizedforeachindividualtoolposition.

TheproposedmethodusesprojecteddrivepatternsandisabletotakecareofmUltipleandeventrimmedpartsurfaces.

1.

INTRODUCTIONFiveaxismachiningoffreeformsurfaceshasmanyadvantagesifcylindricalortoricalcuttersareusedinsteadofballnosecutters.

Comparedtotraditionalthreeaxismachining,thematerialremovalrateincreasesandthemachiningtimereduces.

CommercialCAM-systemswithmulti-axiscapabilityareforcingtheoperatortogivethetoolacertainconstantleadand/ortiltangle(1)withrespecttothesurfacenormal.

Furtherasetofmultipleandtrimmedsurfacescanbemachinedwithinoneoperationthroughtheuseofdrivesurfaces.

Thedrivesurfaceisusedtogeneratetrajectoriesinacontactdrivenway,whicharethenprojectedontothepartsurfaces.

Thetoolorientationiscalculatedbasedeitheronthedrivesurfaceorthepartsurface.

Smallleadanglesarefavourabletothematerialremovalrate,surfaceroughnessandsurfaceaccuracy[2].

But,applyingasmallconstantleadanglealongthemillingpathcancausedifferentproblemslikegougingandvariationsinthescallopheight.

Asasolutionforthis,severalresearchershaveinvestigatedthedynamicoptimizationandadaptationofthetoolinclinationalongthetooltrajectory[1][2].

Themaindrawbackofmostofthesemethodsisthattheyarecontactdriven.

Thismeansthatthetoolisguidedalongtheisoparametriclinesofthepartsurface.

Asaresult,onlysinglesurfaceswithouttrimmingscanbemachined.

Thetoolpathgenerationmethoddescribedinthispaperoptimizesthetoolinclinationineachpointofthepartsurface.

ThesedevelopmentsfitintheframeoftheOPTIMACHproject.

ThegoalsofthisEU-fundedprojectare:Createreliablecollision-anderror-freeNC-programsthroughanon-lineclosedloopsimulationsystem.

Enhancemillingstrategiesinordertoimprovetheachievedsurfacequalitythroughoptimizingthetoolanglew.

r.

t.

theworkpieceandthestep-over.

Theoriginalversionofthischapterwasrevised:Thecopyrightlinewasincorrect.

Thishasbeencorrected.

TheErratumtothischapterisavailableatDOI:IFIPInternationalFederationforInformationProcessing199910.

1007/978-0-387-35392-0_40G.

J.

Ollingetal.

(eds.

),MachiningImpossibleShapesDependingontheprerequIsItesposedbytheusedCAD/CAMsystem,twomainapproacheshavebeenfollowedduringthedevelopment.

Thefirstapproachisbasedontheprototypesoftware,whichhasbeendevelopedinthepastatthedivisionPMAoftheK.

U.

Leuven[2].

Thesecondapproachisamorepracticalsolution,takingawaythedisadvantagesfromthefirstone.

Inbothcases,theinclinationadjustmentisdoneduringthetoolpathgenerationstep(greycolouredblockonFigure1)andnotduringNC-simulation,NC-verificationoronthemachine.

'"Loadll,20-'IFedral,200GOlDx,Y,z,i,j,k,Col/sonme$$llgeIN1T20M6IN2G1X,.

Y.

.

Z.

.

B.

.

C.

.

F300\.

jFigure1.

Overviewofthetoolpathgenerationprocessfora5-axisNC-program2.

FIRSTAPPROACH:NUMERICALOPTIMIZATIONBASEDONTHEANALYTICREPRESENTATIONOFTHEWORKPIECEGEOMETRY.

Forthisfirstapproach,thestandardCAD/CAM-routinesareusedtocalculateeachtoolposture.

Atoolpostureisthecombinationoftoolposition(xyz)andtoolorientation(ijk).

ThetoolinclinationascalculatedbytheCAD/CAM-systemisthenusedasthestartingvaluefortheoptimizationalgorithms.

TheroutinesofthestandardCAD/CAM-systemaregeneratingthetoolposturesinthefollowingmanner(Figure2):,A"".

.

/i)////.

/,///'//gJPSFigure2.

Methodforgeneratingtoolpostures344osAcertaininclinationangleisappliedtothetoolW.

r.

t.

thesurfacenormalofthecorrespondingtooltippointinthepartsurface.

Thetoolisthenprojectedontothepartsurface,whereacontactpoint(CP)isfound.

lftheinclinationangleappliedtothetoolislargeenough,thecontactpointwilllieinfrontofthecutter.

Theoptimizationalgorithm,explainedhereforacylindricalcutter,calculatesthemaximalangleoverwhichthecuttermayberotatedaroundthecontactpoint(CP)tofitascloseaspossibletothepartsurface.

Todothis,thealgorithmconstructsafunction8=f(u,v)representingtherelationshipbetweentheunderlyingsurfaceofthetoolandtheangleoverwhichthecutterisallowedtorotate.

ThisfunctionisthenminimizedtoobtaintheangleTheminimizationprocedureisbasedonatwo-dimensionalNewton-Raphsonmethodstartingfromagivenpointonthepartsurface.

Theresultofthisminimizationmethodisthenearestlocaloptimuminthesurroundingofthegivenpoint.

Figure3.

ElementarydiscinsidethecutterThesizeoftheunderlyingsurfaceforwhichthefunction8=f(u,v)isdefined,isdirectlyrelatedtothetooldiameter.

Thechanceforhavingmorelocalminimaincreaseswiththesizeofthecutter.

Asaconsequence,theanglehastobecalculatedformorethanonepoint,tobesuretofindthesmallestone.

Thisisdonebychoosinganumberofpointsonthebottomofthecylindricalcutter.

Foreachpoint,thefollowingisexecuted:1)Computetheshortestdistancetotheunderlyingpartsurface.

Consequently,thenearestpoint(PI)onthepartsurfaceisfound.

2)Theminimizationisof8=f(u,v)isdonestartingfromthepointPI.

3)Repeatstep2untiltherequestedaccuracyisachieved.

s:;pCPworlDCP_.

.

_.

.

_.

.

_.

.

_.

.

-··'1Z··_.

.

-,:/.

/OSPSThefulltoolwiththeestimatedtoolaxisisprojecteddownonthesurface.

ThisisdonebyusingthestandardCAD/CAMsystems'functionalityfortoolprojection.

Thetoolprojectionreturnsacontactpoint(UCP),whichmightactuallybeinglocatedeverywhereonthebottomofthecutter.

Thetoolaxisisthenac(justed(acertainvalueisaddedforB),basedontherelationshipbetweenthecontactpoint(CP)andthecontactpointreturnedbythetoolprojectionmethodUCP.

TheoalistoetCPascloseasossibletoUCP.

347PSThetoolisprojectedagainwiththenewlyfoundtoolaxis.

Doingthetoolprojectioneverytime,gougingisavoided.

Stepse,0andf)arerepeateduntilacertaincriterionisfulfilled.

Possiblecriterionsare,'UCPcloseenouhtoCP,iJ.

8notositiveanmore,.

.

.

Ingeneral,after2or3iterationstheoptimizedtoolpostureisfound.

Greatcareistakentonotrushthetoolaxisvariations.

Fastdecreasesofthetoolinclinationangle{)cancausethecuttertocutwithhisback.

Thisisnotfavourablefortoolsthatdonotcutwiththecentre(e.

g.

toricalcutters).

Quicklyincreasingthetoolinclinationontheotherhandcanhelpthecuttertoavoidgouging.

Asaresult,thedisturbanceofthetoolinclinationangle{)perdistanceunitislimitedtodifferentvaluesfordecreasingandincreasingtoolaxisinclinationvalues.

4.

\MACHININGRESULTSFortheexperimentalverificationoftheappliedmethod,aworkpiece(dimensions100x100mm)withaconcaveandconvexregion(Figure6)wasmilledoutofureolandaluminiumusingafive-axisMAHO600Cmillingmachine.

Duringtheexperiments,atoricalcutterwithadiameterof20mmandacornerradiusof4mmwasused.

Thenumberoftracksalwaysequalsto20.

ZCIYCFigure6.

Surfacewithconvexandconcaveregion348OneworkpiecewasmilledwiththestandardroutinesoftheCAD/CAM-system.

Forthistest,aminimalinclinationangleof9degreeshasbeenapplied.

Anotherworkpiecewasmilledusingtheoptimizedtoolaxisinclinationroutines.

Thescallopheightofthetwoworkpieceswasinvestigatedusinga3DcoordinatemeasuringmachineCOORD3equippedwithaWolf&Becklaser-scanningprobe.

Figure7showstherawscanningdata.

·202040608J100120·1·2·3Figure7.

Measuredprofileoftheworkpieceintheconvexregion.

Forthisspecificcase,thelargestbenefitoftheoptimizedmethodcomparedwiththestandardmethodwasfoundintheconvexregion.

Intheconcaveregionthecutterwillalwaysbeforcedtoalargertoolinclinationinordertopreventgouging.

5.

CONCLUSION&CONTINUATIONOFWORKTheproposedalgorithmshavebeenimplementedinsideacommercialCAD/CAMsystem.

Experimentsprovethealgorithmsfromthesecondapproachtoberobustandgeneralapplicable.

Sincetheoptimizationofthetoolpostureresultsinalargermaterialremovalrateandasmallerscallop,theneedforanaccuratestep-overcalculationalgorithmisoriginating.

ACKNOWLEDGEMENTSTheOPTIMACHprojectisbeingcarriedoutintheframeoftheIndustrialandMaterialsTechnologiesresearchandtechnologicaldevelopmentprogrammeoftheEuropeanCommunitywithafinancialECcontributionupto1.

923kECU.

MoreinformationaboutthisprojectcanbefoundontheOPTIMACH-webpages:APPENDIXDifferentangularsystemsareinusetodefinethetoolaxisinclination.

Themostpopularsystem,whichalsoisfoundinmostcommercialCAM-systemsisthelead-tiltsystem349(Figure8).

However,theinclination-screwsystemhasadvantagesinthewaythecalculationsaredone,butislessobviousfortheuseroftheCAM-system.

normalvectorZznormalvectortoolcenterpoint0toolcenterpoint0ycpfeeddirectionfeeddirectionFigure8.

Thelead-tiltsystem(lead=aandtilt=P)versustheinclination-screwsystem(inclination=eandscrew=(j).

Theabilityexiststoswitchfromoneangularsystemtoanotherusingtheseformulas:Table1.

TransistionformulasbetweenbothangularsystemsXinclination-screw=cosrp.

sin()X'ead-tilt=smaYinclination-screw=sinrp.

sin()Ylead-tilt=-cosa.

sinf3Zinclinalion-screw=cos()Zlead-tilt=cosa.

cosf3REFERENCES[I]ChoiB.

K.

,ParkJ.

W.

,JunC.

S.

,Cutter-locationdataoptimizationin5-axissurfacemachining,ComputerAidedDesign,vol.

25,no.

6,1993.

y[2]KruthJ.

-P.

,KlewaisP.

,OptimizationandDynamicAdaptationoftheCutterInclinationduringFive-AxisMillingofSculpturedSurfaces,AnnalsoftheCIRP,vol.

43/1,p.

443-448,1994[3]LeeY.

S.

,DecisionSupportEnvironmentforAdvancedMulti-axisCNCMachining,4thIndustrialEngineeringResearchConferenceProceedings,p.

260-268,1995.

[4]LeeY.

S.

,JiH.

,Surfaceinterrogationandmachiningstripevaluationfor5-axisCNCdieandmoldmachining,InternationalJournalofProductionResearch,vol.

35,no.

1,p.

22-252,1995[5]LiS.

X.

,JerardR.

B.

,5-axismachiningofsculpturedsurfaceswithaflat-endcutter,ComputerAidedDesign,vol.

26,no.

3,1994.

[6]MarciniakK.

,GeometricModellingforNumericallyControlledMachining,OxfordUniversityPress,1991.

[7]MarciniakK.

,Influenceofsurfaceshapeonadmissibletoolpositionsin5-axisfacemilling,ComputerAidedDesign,vol.

19,no.

5,1987.

[8]SaarA.

,LauwersB.

,DejongheP.

,Optimisedtoolpathgenerationmethodsforeconomicandcollisionfreemulti-axismachining,Proceedingofthe31stISATAconference,1998.

350

- correctedcornerradius相关文档

- coppercornerradius

- achievedcornerradius

- 9.cornerradius

- tilescornerradius

- 截面cornerradius

- cornercornerradius

UCloud优刻得,新增1核1G内存AMD快杰云机型,服务器2元/首月,47元/年

UCloud优刻得近日针对全球大促活动进行了一次改版,这次改版更加优惠了,要比之前的优惠价格还要低一些,并且新增了1核心1G内存的快杰云服务器,2元/首年,47元/年,这个价格应该是目前市面上最低最便宜的云服务器产品了,有需要国内外便宜VPS云服务器的朋友可以关注一下。UCloud好不好,UCloud服务器怎么样?UCloud服务器值不值得购买UCloud是优刻得科技股份有限公司旗下拥有的云计算服...

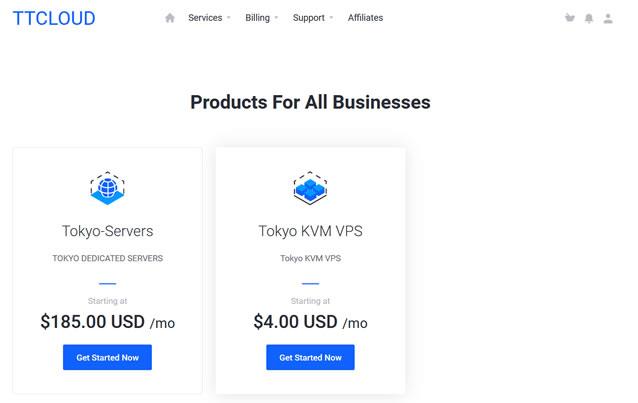

TTcloud(月$70)E3-1270V3 8GB内存 10Mbps带宽 ,日本独立服务器

关于TTCLOUD服务商在今年初的时候有介绍过一次,而且对于他们家的美国圣何塞服务器有过简单的测评,这个服务商主要是提供独立服务器业务的。目前托管硬件已经达到5000台服务器或节点,主要经营圣何塞,洛杉矶以及日本东京三个地区的数据中心业务。这次看到商家有推出了新上架的日本独立服务器促销活动,价格 $70/月起,季付送10Mbps带宽。也可以跟进客户的需求进行各种DIY定制。内存CPU硬盘流量带宽价...

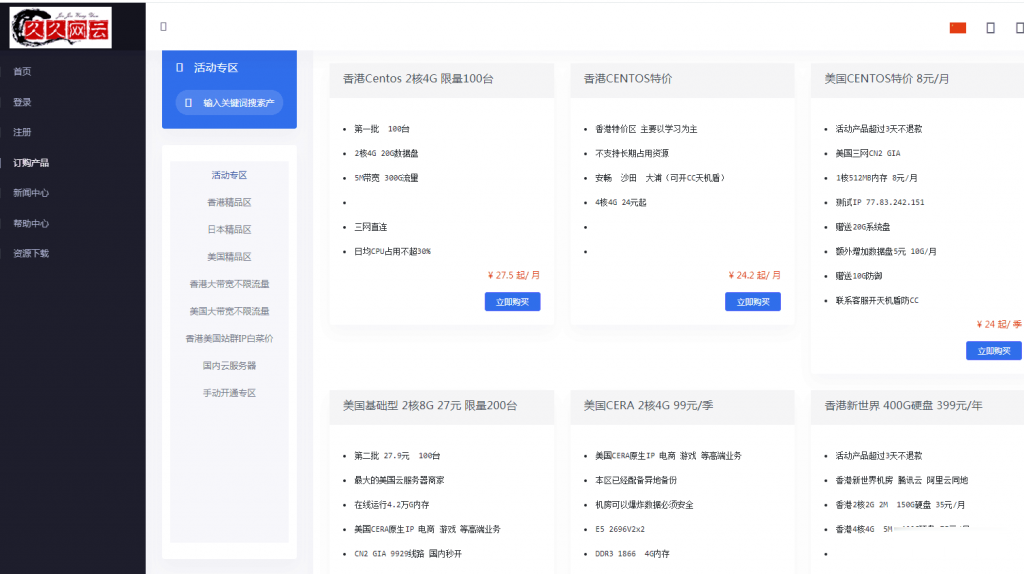

久久网云-目前最便宜的国内,香港,美国,日本VPS云服务器19.9元/月起,三网CN2,2天内不满意可以更换其他机房机器,IP免费更换!。

久久网云怎么样?久久网云好不好?久久网云是一家成立于2017年的主机服务商,致力于为用户提供高性价比稳定快速的主机托管服务,久久网云目前提供有美国免费主机、香港主机、韩国服务器、香港服务器、美国云服务器,香港荃湾CN2弹性云服务器。专注为个人开发者用户,中小型,大型企业用户提供一站式核心网络云端服务部署,促使用户云端部署化简为零,轻松快捷运用云计算!多年云计算领域服务经验,遍布亚太地区的海量节点为...

cornerradius为你推荐

-

photoimpact教程Ulead PhotoImpact 如何把英文版的变成中文的!找不到光驱我的电脑里找不到光驱人人时光机现在世界上有时光机吗bluestacks安卓模拟器BlueStacks如何安装使用?1433端口路由器1433端口怎么开启9flashIE9flash模块异常。直播加速有没有软件使已经下载好了的视频播放加速,例如30分钟的视频15分钟或者20分钟播放完宕机人们说的宕机是什么意思二层交换机集线器和二层交换机,三层交换机的区别机械键盘轴机械键盘蓝轴有什么作用