putwww.299pp.com

www.299pp.com 时间:2021-03-19 阅读:()

Availableonlinewww.

jocpr.

comJournalofChemicalandPharmaceuticalResearch,2014,6(7):1916-1921ISSN:0975-7384CODEN(USA):JCPRC51916Reverselogisticsnetwork:AliteraturereviewTaoYe1*andYinZhenhua21SchoolofInformationEngineering,HangzhouDianziUniversity,Xiasha,Hangzhou,Zhejiang,China2EngineeringDivision,WujiangPolytechnicSchool,Songling,Wujiang,Jiangsu,ChinaABSTRACTThepurposeofthisarticleistoconductareviewofthereverselogisticsnetworkliteratures,especiallythosepublishedeversince2000.

Wehopetofindoutcharacteristicsintheresearchandpossibleopportunitiesforfurtherresearch.

Contentanalysisisappliedinthisarticletoreviewthepublishedliteraturesinbooksandconferenceproceedings,andarticlesobtainedfromelectronicsources.

Mostresearchfocusesonlyonasmallareaofreverselogisticsnetwork.

Manyliteraturesinreverselogisticsnetworkdesignfocusoncasestudy,especiallyonelectricalandelectronicequipmentrecycling.

Manyquantitativemodelshavebeendevelopedforreverselogisticsnetworkdesign.

Reverselogisticsnetworkmodelscanbeclassifiedasclosed-loopnetworkmodel,genericmodel,stochasticmodeland3PLsmodel.

Researchersfocusoncasestudy,quantitymodelandclosed-loopnetworkmodel.

Inparticular,closed-loopnetworkmodelhasbeenreceivingmuchmoreattentionfrom2000.

However,theresearchesonmodelsfor3PLsarerelativelylittle.

Keywords:Reverselogisticsnetwork,Casestudy,QuantitativemodelINTRODUCTIONSustainabilityhasbecomeamajorconcerninthedevelopmentofhumansociety.

Sustainabilityrequirestosolvesomecomplexissuesinvolvingsocial,technicalandlegislativefactors,suchashowtopreventtheenvironmentaldeteriorationcausedbythegenerationofwastes,howtominimizethegenerationofwastesandhowtoenhancethevaluerecoveryfromthewastes.

Reverselogisticsnetworkishelpfultomeetthisrequirementbecauseitsmaintaskistocollectandtransportusedproductsandpackagesbasedonthebalanceofcostandenvironment.

Itcantakeplacethroughtheoriginalforwardchannel,aseparatereversechannelandcombinationsoftheforwardandthereversechannel.

Ontheotherside,goodreverselogisticsnetworkisimportantforfirmstogainmoreprofit.

IntegrationandoptimizationofreverselogisticsnetworkhasbecomeaneffectivewaytokeepandimprovecompetitiveadvantageforHP,GEandIBM[1].

Thepurposeofthisarticleistoprovideareviewoftheresearchofreverselogisticsnetworkeversince2000.

Therestofthearticleisorganizedasfollows.

Inthesecondsectionresearchmethodologyisdiscussed.

Inthethirdsection,theresultofreviewispresentedandthissectionisdividedfurtherintosubsectionstohighlightvariousfactorsthatareimportanttotheresearch.

Inthelastsectionconclusionswithsomethoughtsonfurtherresearcharemade.

EXPERIMENTALSECTIONThemethodofcontentanalysisisappliedinthisliteraturereview.

Asanobservationalresearchmethod,contentanalysisisoftenusedtosystematicallyevaluatethesymboliccontentofallformsofrecordedcommunication.

Thismethodisalsohelpfultoidentifytheliteratureintermsofvariouscategoriesforcreatingresearchopportunities.

Al-MashariandZairiusedittoanalyzetheimplementationofSAPR/3forre-engineeringthesupplychainusingTaoYeandYinZhenhuaJ.

Chem.

Pharm.

Res.

,2014,6(7):1916-19211917enterpriseresourcesystems[2].

ItwasalsousedbyByrdandDavidsontoexaminetheimpactofinformationtechnologyonsupplychainandbyMarascoinareviewofliteratureonthirdpartylogistics[3].

Thereviewisbasedonthepublishedliteraturesinbooksandconferenceproceedings,andarticlesobtainedfromelectronicsourcesincludingGoogleScholar,ScienceDirect,EmeraldInsight,andIndersciencedatabases.

Keywordssuchas"reverselogisticsnetwork","reverselogistics","recycling","remanufacturing","productreturns","productrecovery","end-of-lifeproducts","closed-loopsupplychains"and"greensupplychain"wereusedtofindrelatedliteratures.

LITERATUREREVIEW3.

1OverviewAccordingtothewidelyaccepteddefinitionofreverselogisticsmadebyFleischmann"reverselogisticsnetworkistheprocessofplanning,implementingandcontrollingtheefficient,effectiveinboundflowandstorageofsecondarygoodsandrelatedinformation,oppositetothetraditionalsupplychaindirectionsforthepurposeofrecoveringvalueandproperdisposal",reverselogisticsnetworkcanberegardedastheconfigurationofnodesandthearrangementoflinesinreverselogisticssystem,reverselogisticsnetworkcoversthreemainsub-fields——distributionplanning,inventorycontrol,andproductionplanning[4-6].

Researchonreverselogisticsnetworkhasbeengrowingsincethe1970s.

Mostresearchaboutthestrategiesandmodelsonreverselogisticsnetworkcanbeseeninthepublicationsinandafterthe1980s.

However,effortstosynthesizetheresearchinanintegratedbodyofknowledgeseemcomparativelylimited.

Mostresearchfocusesonlyonasmallareaofreverselogisticsnetwork,suchasnetworkdesign,productionplanningorenvironmentalissues.

Forinstance,astudywascarriedoutfromtheperspectivesofdistributionplanning,inventorycontrolandproductionplanning[4].

Anotherstudy,asareviewofreverselogisticsnetworkliterature,focusedonthetransportationandpackaging,purchasingandenvironmentalaspects[7].

Theinteractionsbetweensustainabilityandsupplychainswasstudiedbyconsideringenvironmentalissuesregardingproductdesign,productlifeextensionandproductrecoveryatend-of-life[8].

Morestudiescanbefoundintheliteraturereviewonreverselogisticsnetworkpublishedbetween1995and2005byfocusingonmanagementoftherecovery,distributionofend-of-lifeproducts,productionplanningandinventorymanagementandsupplychainmanagementissues[9].

Designandoptimizationofreverselogisticsnetworkisamajorfocusintherecentyears.

Thisincludesthenetworkstructure,thenumberoflayers,thetypeofnecessaryfacilitiesaswellasthetechnologyneededtobeemployed.

Theresponsiblepartiesneedtodecidethenumberoffacilitiesrequired,theircapacitiesandtheirmostappropriatelocationsaswell.

Inthedesignandoptimizationofareverselogisticsnetworkseveralissuesshouldbeconsidered:actorsinreverselogisticnetwork,functionstobecarriedoutandtherelationbetweentheforwardandreverselogisticnetwork.

Someresearchershaveproposedseveraldesignprinciplesforreverselogisticnetwork[10-12].

However,theseprincipleswerelimitedincertaincircumstanceandcannotformawidelyacceptedcriterion.

Designprincipleswereputforwardforclosed-looplogisticnetworkaccordingtocharacteristicsofreverselogisticsfromtheperspectivesofeconomics,environmentandlogisticschannel[13].

Theprinciplesincludeselectioncriterionofsuppliers,productionlifecycle(PLC)analysis,productquality,andrecoverypercentage,andsoon.

Table1DifferencesbetweenreverselogisticsnetworkandforwardlogisticnetworkReverseLogisticsNetworkForwardLogisticsNetworkthroughstandardchanneldrivenbyexternalforcedefinitedestinationindefinitedestinationcleardisposalmodeuncertaindisposalmodeforrecyclesuniformpricespricesinfluencedbymanyfactorsspeedisveryimportantspeedissubordinateuniforminventoryvariousinventoriesforvariousproductsproductsexistintheeasy-to-be-managedstagesofthelifecyclerecycledproductsexistincomplicatedstagesdirectnegotiationsamongparticipantsofthesupplychaincomplexandvariantnegotiationprocessreal-timetracingforproductsbeingsaleddifficulttotracehowrecycledproductsaretreatedcanbepredicteduniformlydifficulttobepredictedtransportationisunilateraltomultilateraltransportationismultilateraltounilateralhomogenousqualityofproductsheterogenousqualityofproductsuniformpackagesofproductspackagesofproductsoftendamaged3.

2ComparisonbetweenreverselogisticsnetworkandforwardlogisticnetworkBecauseofthehighersupplyuncertaintyinquality,quantity,timeandsomeotheraspects,reverselogisticsnetworkismuchmorecomplicatedthantraditionalforwardlogisticnetwork.

Regardingsupplychainperformance,Fleischmannpointedoutthedistinctionsbetweenreverselogisticnetworkandforwardlogisticnetwork,i.

e.

recoveryproductshavetobeinspectedandclassificationinreverselogisticswithhigheruncertainty.

TheTaoYeandYinZhenhuaJ.

Chem.

Pharm.

Res.

,2014,6(7):1916-19211918distinctionsshouldbeconsideredindesigningandoptimizingreverselogisticsnetwork[14].

MoredifferencesputforwardbytheresearcherscanbeseeninTable1[15-18].

3.

3CaseStudiesforreverselogisticsnetworkManyresearchershavecarriedoutcasestudiesbecauseareverselogisticsnetworkisusuallycomplicated.

Thecaseswerechosenfromvariousindustriesorproductssuchasbatteryrecycling,paperrecycling,electronicequipment,sandrecyclingandnuclearpower.

.

Avehicleroutingapproachwaspresentedforthetransportofend-of-lifeconsumerelectronicgoodsforrecyclinginSouthKoreatominimizethedistanceoftransportationofend-of-lifegoodscollectedbylocalauthoritiesandmajormanufacturers'distributioncenterstofourregionalrecyclingcenterslocated[19].

Alinearmulti-objectiveoptimizationmodelwasusedtooptimizetheoperationsofboththenuclearpowergenerationandthecorrespondinginducedwastereverselogisticsinChina[20].

Amulti-periodMILPmodelwasestablishedforcarpetrecyclinginEnglandtoanalyzeasetofalternativescenariosidentifiedbythedecisionmakerandprovidedanear-optimalsolutionfornetworkdesign[21].

AnewMILPmodelwasputforwardtooptimizetheinfrastructuredesignandthereversenetworkflowfortherecoveryofelectricalappliancesandcomputersinTaiwan,withcomputationalresultsforthescenariosofdifferentproductreturnratesandoperationconditions[22].

ThereverselogisticsnetworkofanelectronicequipmentremanufacturingfirminAmericawasanalyzed,andamulti-productcapacitatedwarehouselocationMILPwaspresentedandsolvedtoobtainoptimalityfordifferentsupplyanddemandscenarios[23].

AnotherMILPmodelwasestablishedforthemulti-echelonproductrecoverynetworkdesignwhichfocusedontheremanufacturingofacertaintypeofcopyphotocopier[6].

InthisstudyanLPsolverwasalsousedtogettheoptimalsolutionfortheinstancesofsmallproblemsize.

MorecasestudiescanbefoundinTable2.

Table2CasestudiesforreverselogisticsnetworkCaseLiteratureBatteryrecycling[24]Wasteofelectricalandelectronicequipment[5]EOLelectronicandelectronicproducts[25]EOLvehicles[10]Originalequipmentmanufacturers[17]Electronicgoods[19]Paperrecycling[26]EOLcomputerproducts[27]Nuclearpowergeneration[20]Metal-mechaniccompany[14]Carpetrecycling[28]Automotiveindustry[29]Sandrecycling[30]Electronicwaste[31]Wasteofelectricalandelectronicequipment[18]Carpetrecycling[21]Spentbatteries[32]Computersandhomeappliances[22]Electronicequipmentremanufacturingcompany[23]Photocopiers[6]Carpetmaterials[33]Sandrecycling[24]3.

4QuantitativeModelsforreverselogisticsnetworkManyquantitativemodelshavebeenproposedforreverselogisticsnetworkdesignintherecentyears,includingmixedintegerlinearprogramming(MILP)model,mixedintegernonlinearprogramming(MINLP)model,mixedintegergoalprogramming(MIGP)modelandlinearmulti-objectiveprogramming(LMOP)model.

Amulti-objectiveandmulti-periodMILPmodelwasestablishedforreverselogisticnetworkdesignformodularizedproductswhichdeterminesthenumberofexistingforwardflowfacilitiestobeusedandthenumberofdedicatedfacilitiestobesetupforhandlingreturnflows[34].

Amixedintegergoalprogramming(MIGP)modelwasestablishedtodeterminethefacilitylocation,routeandflowofdifferentvarietiesofrecyclablewastepaperinthemulti-item,multi-echelonandmulti-facilityenvironment[26].

AsimulationmodelofareverselogisticsnetworkwasusedtocollectEOLappliances[16].

Withtemporalconsolidationissuesinamultipleplanninghorizon,Minandhiscolleaguesputforwardanonlinearmixedintegerprogrammingmodelandageneticalgorithmtosolvethereverselogisticsprobleminvolvingproductreturnsinothertwoarticles[35].

Anonlinearintegerprogramwasproposedtosolvethemulti-echelon,multicommodityclosedloopnetworkdesignprobleminvolvingproductreturnsinanotherarticleoftheauthors[36].

Alinearmulti-objectiveoptimizationmodelwaspresentedtooptimizetheoperationsofboththenuclearpowergenerationandthecorrespondinginducedwastereverselogistics[37].

TheauthorTaoYeandYinZhenhuaJ.

Chem.

Pharm.

Res.

,2014,6(7):1916-19211919incorporatedfactorssuchastheoperationaldangersinducedinboththepowergenerationandreverselogisticsprocessesinthemodelformulation.

AnMILPmodelwasputforwardtoanalyzetheimpactofproductrecoveryonlogisticsnetworkdesignandaheuristicalgorithmwasappliedtoobtainthesolutionforcaseswithlargeproblemsize[12].

MorequantitativemodelscanbefoundinTable3.

Table3QuantitativemodelsinreverselogisticsnetworkQuantitativemodelLiteratureLinearmulti-objectiveprogramming[20],[37]Mixedintegergoalprogramming[26]Mixedintegerlinearprogramming[38],[39],[25],[40],[11],[41],[42],[43],[44],[45],[30],[34],[21],[46],[4],[22],[23],[6]Mixedintegernonlinearprogramming[47],[35],[36]Amajorissueinthereversedistributionishowtointegrateforwardchannelandreversechannel[4].

Thestructureofreverselogisticsnetworkhasastronginfluenceontheperformanceofforwardlogisticsnetworkandviceversaastheysharealotofresourcessuchastransportandwarehousecapacity.

Separatelydesigningforwardlogisticsandreverselogisticsresultsinsub-optimaldesignswithrespecttocosts,servicelevelsandresponsiveness,sotheintegrationofforwardandreverselogisticsnetworkshasdrawnattentionofmanyresearchers.

Aclosed-loopsupplychain(CLSC)consistsofbothforwardsupplychainandreversesupplychain.

Correspondingly,aclosed-looplogisticnetworkconsistsofbothforwardlogisticnetworkandreverselogisticnetwork.

Bystudyingacaseofphotocopierremanufacturingandacaseofpaperrecycling,Fleischmannpointedoutthatthereispossibilityforcostsavingsifoneundertookanintegratedviewratherthanasequentialdesignoftheforwardandreversedistributionnetworks[4].

Ahybridmethodwasdevelopedtoestablishaclosed-loopsupplychainmodelforspentbatteries.

Themodelincludesatwo-stagefacilitylocationoptimizationproblemandwasappliedunderdifferentscenariosforasteelmakingprocess[32].

Alinearmultiobjectiveprogrammingmodelwasformulatedtooptimizetheoperationsofbothintegratedlogisticsandcorrespondingused-productreverselogisticsinagivengreen-supplychain,withtheconsiderationoftheusedproductreturnratioandcorrespondingsubsidiesfromgovernmental[37].

Agenericstochasticmodelwaspresentedforthedesignofnetworkscomprisingbothsupplyandreturnchannelsinaclosedloopsystem,whichissolvedbytheintegerL-shapedmethod[43].

Atwo(0,1)levelmixedintegerprogrammingmodelofanuncapacitatedfacilitylocationwasproposed,inwhichsimultaneouslyforwardandreverseflowsandtheirmutualinteractionswereconsidered[44].

Thelogisticsnetworkdesignforend-of-leasecomputerproductswasdiscussedandadeterminedprogrammingmodelforsystematicallymanagingforwardandreverseslogisticsflowswasdeveloped[27].

Anintegratedmodelforsupplychainmanagementwasproposed,wheretheoperationofthereversechainhadbeenbuiltbasedontheexistingprocessesoftheforwardchain,andthismodelhadbeenvalidatedinacompanyfromthemetal-mechanicsector[14].

Afacilitylocation-allocationmodelforredesigningclosed-loopservicenetworkofacomputermanufacturerwasdeveloped.

Themodelconsideredthepossibilityofthenetworkspanningacrossseveralcountriesandmulti-periodplanninghorizons[48].

Aclosedloopmixedintegerlinearprogrammingmodelwasdevelopedtodeterminerawmateriallevel,productionlevel,distributionandinventorylevel,disposallevel,andrecyclinglevelatdifferentfacilitieswiththeobjectiveofminimizingthetotalsupplychaincost[38].

Manyreverselogisticnetworkmodelshaveappearedincasestudies,sotheylackgeneralityindifferentsituations.

Someresearchershavetriedtoproposegeneralizedmodels.

Ageneralquantitativemodelwaspresentedforproductrecovery,inwhichrepairingandremanufacturingwereconsideredsimultaneously[42].

Anothergeneralizedmodelofreverselogisticsnetworkwasestablishedasamixedintegerformulation,wherecapacitylimits,multi-productmanagementanduncertaintyonproductdemandsandreturnswereconsidered[45].

Fleischmannandhiscolleaguesalsoputforwardsuchamodelforthedesignofreverselogisticsnetworks,andpresentedageneralizedfacilitylocationmodel(MILP)tointegratetheforwardandreversechainswithabalanceconstraintthatthetotalreturnofeachfactorycannotexceeditstotalproduction[4].

Uncertaintyisanotherimportantcharacteristicofproductrecoverybecausethequantityandthequalityofusedproductsaremoredifficulttocontrolandestimateinreverseflow.

Someresearchershaveaddressedthisissueunderstochasticenvironment.

Aperiodicreviewmodelwasestablishedforproductrecoveryinstochasticremanufacturingsystemswithmultiplereuseoptions[49].

Astochasticprogrammingapproachwaspresentedtogetherwithadeterminedlocationmodelforproductrecoverynetworkdesigntodealwithsomeuncertainties.

However,thisapproachcanonlysolveasmallnumberofscenariosoftheuncertainproblemparameters[30].

Amulti-periodandmulti-echelonforward-reverselogisticsnetworkdesignriskmodelwasdevelopedbyEl-Sayedandhiscolleagues.

Themodelwasformulatedasastochasticmixedintegerlinearprogramming(SMILP)decisionmakingform.

Butitcanonlybeusedforsingleitemandsingleproductproblems[11].

AtwostagestochasticprogrammingmodelwasputforwardbyLeeandhisTaoYeandYinZhenhuaJ.

Chem.

Pharm.

Res.

,2014,6(7):1916-19211920colleagues.

Theyintegratedthesampleaverageapproximationmethodwithaheuristicalgorithmbasedonsystemanalysis[50].

Someresearchershaveusedquantitativemodelstostudyreversenetworkconcerningthird-partylogistics(3PLs).

Thereasonisprobablythattherearemajoradvantagesassociatedwith3PLsprovidershandlingthereverselogisticsforcompanies.

First,the3PLsprovidershaveexpertise,sophisticatedlogisticnetworks,ITtechnologyandthecapabilitytooperatesystemsefficiently[51].

Second,thesameassets(investment)ofthird-partyproviderscanbeusedinvariouscontractualrelationshipsandthusprovideeconomiesofscalewhenemployed[52].

Rupnowandotherresearchersshowedthemultiplebenefitsthatcompaniesusing3PLsservicetypicallyexperience[1].

Themostfrequentlymentionedadvantagesarecostreduction,improvedexpertiseandaccesstodata,improvedoperationandcustomerservicesandtheabilitytofocusoncorecompetenciesandflexibility.

Amixedintegernonlinearprogrammingmodelwasappliedforthedesignofadynamicintegrateddistributionnetworkfor3PLs.

Inordertohandletherealisticallysizedproblem,ageneticalgorithmwaspresented[47].

Aclosedloopreverselogisticsnetworkproblemwasestablishedinwhichmanufacturerstookadvantageofa3PLsystemforthepost-saleservice[40].

Amixed-integerprogrammingmodelandageneticalgorithmwereputforwardtosolvethereverselogisticsprobleminvolvingthelocationandallocationofrepairfacilitiesfor3PLs[41].

CONCLUSIONThispapersummarizestheresearchmethodologyforreverselogisticsnetworkascasestudyandquantityanalysis,andclassifiesreverselogisticsnetworkmodelsintofourmajorcategories:closed-loop,genericmodel,stochasticmodeland3PLs.

Ourreviewshowsthatcasestudyforreverselogisticsnetworkhaskeptahighproportioninthelastdecadewhilequantitymodelandclosed-loopnetworkhavereceivedgrowingattention.

Theproducttypescoveredincasestudyarestillnotextensiveandlimitedinseveralsimilarproducts.

Itisachallengetoextendcasestudyforreverselogisticsnetworktomostproducts.

Moreover,thegeneralityofmodelforreverselogisticsnetworkisnotsatisfactoryastherearealotofdifferentsituationsineachlogisticnetwork.

Inaddition,reverselogisticsnetworkdesignfor3PLshasnotfullybeenaddressed.

AcknowledgementsThisresearchwasfinanciallysupportedbyResearchStartProjectofHangzhouDianziUniversity(KYS035609044).

REFERENCES[1]SSeuring.

DecisionSupportSystems,2013,54(4),1513-1520.

[2]KSubulan;ATasan.

InternationalJournalofAdvancedManufacturingTechnology,2013,66(1),251-269.

[3]GCSouza.

DecisionScience,2013,44(1),7-38.

[4]MFleischmann;PBeullens;JMBloemhof-Ruwaard;LNVWassenhove.

ProductionandOperationsManagement,2001,10(2),156-173.

[5]MGrunow;CGobbi.

CIRPAnnals-ManufacturingTechnology,2009,58(1),391-394.

[6]HRKrikke;AVanHarten;PCSchuur.

ORSpectrum,1999,21(3),381-409.

[7]VJayaraman;YLuo.

AcademyofManagementPerspectives,2007,21(2),56-73.

[8]JELee;KDLee,Kang-Dae.

InternationalJournalofInnovativeComputingInformationandControl,2012,8(7),4483-4495.

[9]SARubio;TChamorro;FJMiranda.

Int.

J.

ofProductionResearch,2008,46(4),1099-1120.

[10]RCruz-Rivera;JErtel.

EuropeanJournalofOperationalResearch,2009,196(3),930-939.

[11]MEl-Sayed;NAfia;AEl-Kharbotly.

Computers&IndustrialEngineering,2010,58(3),423-431.

[12]MFleischmann;HRKrikke;RDekker;SDPFlapper.

Omega,2000,28(6),653–666.

[13]KHarold;CPPappis;GTTsoulfas;J.

Bloemhof-Ruwaard.

ERIMReportSeriesResearchinManagement,2001,62(2),138-147.

[14]MVdelaFuente;LRos,L;MCardos,M.

Int.

J.

ProductionEconomics,2008,111(2),782-792.

[15]SKSrivastava.

InternationalJournalofManagementReviews,2007,9(1),53-80.

[16]SKara;FRugrungruang;HKaebernick.

Int.

J.

ProductionEconomics,2007,106(1),61-69.

[17]AMutha;SPokharel.

Computers&IndustrialEngineering,2009,56(1),334-346.

[18]GWalther;TSpengler.

Int.

J.

ofPhysicalDistributionandLogisticsManagement,2005,35(5),337-361.

[19]HKim;JYang;KLee.

TransportationResearchPartD,14(5),291-299.

[20]JBSheu.

TransportationResearchPartE,2008,44(1),19-46[21]MRealff;JAmmons;DNewton.

IEEEIEEMTransactions,2004,36(8),767-776.

[22]LHShih.

Resources,ConservationandRecycling,2001,32(1),55-72[23]VJayaraman;J.

Guige;RSrivastava.

JournaloftheOperationalResearchSociety,1999,vol.

50,pp.

497-508TaoYeandYinZhenhuaJ.

Chem.

Pharm.

Res.

,2014,6(7):1916-19211921[24]AIBarros;RDekker,R;VScholten.

EuropeanJournalofOperationalResearch,1998,110(2),199-214.

[25]AXanthopoulos;EIakovou.

WasteManagement,2009,29(5),1702-1711.

[26]PKPatia;PVratb;PKumar.

Omega,2008,36(3),405-417[27]DHLee;MDong.

TransportationResearchPartE,2008,44(3),455-474.

[28]MBiehl;EPrater;MJRealff.

Computers&OperationsResearch,2007,34(2)443-463.

[29]FSchultmann;MZumkeller;ORentz,O.

EuropeanJournalofOperationalResearch,2006,171(3),1033-1050.

[30]OListes;RDekker.

EuropeanJournalofOperationalResearch,2005,160(1),268-287.

[31]ANagurney;FToyasaki.

TransportationResearchPartE,2005,41(1),1-28.

[32]FSchultmann;BEngels;ORentz.

Interfaces,33(6),57-71.

[33]DLouwers;BJKip;EPeters;ESouren,E;SDP.

Computers&IndustrialEngineering,1999,36(4),855-869.

[34]RDKusumastuti;R.

Piplani;GLim.

ProceedingsofIEEEinternationalengineeringmanagementconference,1stEdition,IEEE,Singapore,2004;1239-1243.

[35]HMin;CSKo;HJKo.

Computers&IndustrialEngineering,2006,51(2),309-320.

[36]HMin;HJKo;BIPark.

Int.

J.

Logist.

Syst.

Manage.

,2005,1(4),382-404.

[37]JBSheu;YHChou;CCHu.

Transport.

Res.

PartE:Logist.

Transport.

Rev.

,2005,41(4),287-313.

[38]GKannan;PSasikumar;KDevika.

AppliedMathematicalModelling,2010,34(3),655-670.

[39]MIGSalema;APBarbosa-Povoa;AQNovais.

EuropeanJournalofOperationalResearch,2010,203(2),3363-3349.

[40]FDu;GWEvans.

Computers&OperationsResearch,2008,35(8),2617–34.

[41]HMin;HJKo.

Int.

J.

ProductionEconomics,2008,113(1),176-192.

[42]YZhou;SWang.

J.

ofTransportationSystemsEngineeringandInformationTechnology,2008,8(3),71-78.

[43]OListes.

Computers&OperationsResearch,2007,34(2),417-442.

[44]ZLu;NBostel.

Computers&OperationsResearch,2007,34(2),299-323.

[45]MIGSalema;APBarbosa-Povoa;AQNovais.

EuropeanJournalofOperationalResearch,2007,179(3),1063-1077.

[46]FSchultmann;BEngels;ORentz.

Interfaces,2003,33(6),57-71.

[47]HJKo;GWEvans.

Computers&OperationsResearch,2007,34(2),346–366.

[48]RDKusumastuti;RPiplani;GLim.

Int.

J.

ProductionEconomics,2008,111(2),244-260.

[49]KAInderfuth;GKok;SFlapper.

EuropeanJournalofOperationalResearch,2010,133(1),130-152.

[50]DHLee;DDong.

TransportationResearchPartE,2009,45(1),61-71.

[51]SAElliff.

TheJournalofCommerce,2004,12(2).

1-2.

[52]TSkjoett-Larsen.

Int.

J.

ofPhysicalDistribution&LogisticsManagement,2004,30(2),112-127.

jocpr.

comJournalofChemicalandPharmaceuticalResearch,2014,6(7):1916-1921ISSN:0975-7384CODEN(USA):JCPRC51916Reverselogisticsnetwork:AliteraturereviewTaoYe1*andYinZhenhua21SchoolofInformationEngineering,HangzhouDianziUniversity,Xiasha,Hangzhou,Zhejiang,China2EngineeringDivision,WujiangPolytechnicSchool,Songling,Wujiang,Jiangsu,ChinaABSTRACTThepurposeofthisarticleistoconductareviewofthereverselogisticsnetworkliteratures,especiallythosepublishedeversince2000.

Wehopetofindoutcharacteristicsintheresearchandpossibleopportunitiesforfurtherresearch.

Contentanalysisisappliedinthisarticletoreviewthepublishedliteraturesinbooksandconferenceproceedings,andarticlesobtainedfromelectronicsources.

Mostresearchfocusesonlyonasmallareaofreverselogisticsnetwork.

Manyliteraturesinreverselogisticsnetworkdesignfocusoncasestudy,especiallyonelectricalandelectronicequipmentrecycling.

Manyquantitativemodelshavebeendevelopedforreverselogisticsnetworkdesign.

Reverselogisticsnetworkmodelscanbeclassifiedasclosed-loopnetworkmodel,genericmodel,stochasticmodeland3PLsmodel.

Researchersfocusoncasestudy,quantitymodelandclosed-loopnetworkmodel.

Inparticular,closed-loopnetworkmodelhasbeenreceivingmuchmoreattentionfrom2000.

However,theresearchesonmodelsfor3PLsarerelativelylittle.

Keywords:Reverselogisticsnetwork,Casestudy,QuantitativemodelINTRODUCTIONSustainabilityhasbecomeamajorconcerninthedevelopmentofhumansociety.

Sustainabilityrequirestosolvesomecomplexissuesinvolvingsocial,technicalandlegislativefactors,suchashowtopreventtheenvironmentaldeteriorationcausedbythegenerationofwastes,howtominimizethegenerationofwastesandhowtoenhancethevaluerecoveryfromthewastes.

Reverselogisticsnetworkishelpfultomeetthisrequirementbecauseitsmaintaskistocollectandtransportusedproductsandpackagesbasedonthebalanceofcostandenvironment.

Itcantakeplacethroughtheoriginalforwardchannel,aseparatereversechannelandcombinationsoftheforwardandthereversechannel.

Ontheotherside,goodreverselogisticsnetworkisimportantforfirmstogainmoreprofit.

IntegrationandoptimizationofreverselogisticsnetworkhasbecomeaneffectivewaytokeepandimprovecompetitiveadvantageforHP,GEandIBM[1].

Thepurposeofthisarticleistoprovideareviewoftheresearchofreverselogisticsnetworkeversince2000.

Therestofthearticleisorganizedasfollows.

Inthesecondsectionresearchmethodologyisdiscussed.

Inthethirdsection,theresultofreviewispresentedandthissectionisdividedfurtherintosubsectionstohighlightvariousfactorsthatareimportanttotheresearch.

Inthelastsectionconclusionswithsomethoughtsonfurtherresearcharemade.

EXPERIMENTALSECTIONThemethodofcontentanalysisisappliedinthisliteraturereview.

Asanobservationalresearchmethod,contentanalysisisoftenusedtosystematicallyevaluatethesymboliccontentofallformsofrecordedcommunication.

Thismethodisalsohelpfultoidentifytheliteratureintermsofvariouscategoriesforcreatingresearchopportunities.

Al-MashariandZairiusedittoanalyzetheimplementationofSAPR/3forre-engineeringthesupplychainusingTaoYeandYinZhenhuaJ.

Chem.

Pharm.

Res.

,2014,6(7):1916-19211917enterpriseresourcesystems[2].

ItwasalsousedbyByrdandDavidsontoexaminetheimpactofinformationtechnologyonsupplychainandbyMarascoinareviewofliteratureonthirdpartylogistics[3].

Thereviewisbasedonthepublishedliteraturesinbooksandconferenceproceedings,andarticlesobtainedfromelectronicsourcesincludingGoogleScholar,ScienceDirect,EmeraldInsight,andIndersciencedatabases.

Keywordssuchas"reverselogisticsnetwork","reverselogistics","recycling","remanufacturing","productreturns","productrecovery","end-of-lifeproducts","closed-loopsupplychains"and"greensupplychain"wereusedtofindrelatedliteratures.

LITERATUREREVIEW3.

1OverviewAccordingtothewidelyaccepteddefinitionofreverselogisticsmadebyFleischmann"reverselogisticsnetworkistheprocessofplanning,implementingandcontrollingtheefficient,effectiveinboundflowandstorageofsecondarygoodsandrelatedinformation,oppositetothetraditionalsupplychaindirectionsforthepurposeofrecoveringvalueandproperdisposal",reverselogisticsnetworkcanberegardedastheconfigurationofnodesandthearrangementoflinesinreverselogisticssystem,reverselogisticsnetworkcoversthreemainsub-fields——distributionplanning,inventorycontrol,andproductionplanning[4-6].

Researchonreverselogisticsnetworkhasbeengrowingsincethe1970s.

Mostresearchaboutthestrategiesandmodelsonreverselogisticsnetworkcanbeseeninthepublicationsinandafterthe1980s.

However,effortstosynthesizetheresearchinanintegratedbodyofknowledgeseemcomparativelylimited.

Mostresearchfocusesonlyonasmallareaofreverselogisticsnetwork,suchasnetworkdesign,productionplanningorenvironmentalissues.

Forinstance,astudywascarriedoutfromtheperspectivesofdistributionplanning,inventorycontrolandproductionplanning[4].

Anotherstudy,asareviewofreverselogisticsnetworkliterature,focusedonthetransportationandpackaging,purchasingandenvironmentalaspects[7].

Theinteractionsbetweensustainabilityandsupplychainswasstudiedbyconsideringenvironmentalissuesregardingproductdesign,productlifeextensionandproductrecoveryatend-of-life[8].

Morestudiescanbefoundintheliteraturereviewonreverselogisticsnetworkpublishedbetween1995and2005byfocusingonmanagementoftherecovery,distributionofend-of-lifeproducts,productionplanningandinventorymanagementandsupplychainmanagementissues[9].

Designandoptimizationofreverselogisticsnetworkisamajorfocusintherecentyears.

Thisincludesthenetworkstructure,thenumberoflayers,thetypeofnecessaryfacilitiesaswellasthetechnologyneededtobeemployed.

Theresponsiblepartiesneedtodecidethenumberoffacilitiesrequired,theircapacitiesandtheirmostappropriatelocationsaswell.

Inthedesignandoptimizationofareverselogisticsnetworkseveralissuesshouldbeconsidered:actorsinreverselogisticnetwork,functionstobecarriedoutandtherelationbetweentheforwardandreverselogisticnetwork.

Someresearchershaveproposedseveraldesignprinciplesforreverselogisticnetwork[10-12].

However,theseprincipleswerelimitedincertaincircumstanceandcannotformawidelyacceptedcriterion.

Designprincipleswereputforwardforclosed-looplogisticnetworkaccordingtocharacteristicsofreverselogisticsfromtheperspectivesofeconomics,environmentandlogisticschannel[13].

Theprinciplesincludeselectioncriterionofsuppliers,productionlifecycle(PLC)analysis,productquality,andrecoverypercentage,andsoon.

Table1DifferencesbetweenreverselogisticsnetworkandforwardlogisticnetworkReverseLogisticsNetworkForwardLogisticsNetworkthroughstandardchanneldrivenbyexternalforcedefinitedestinationindefinitedestinationcleardisposalmodeuncertaindisposalmodeforrecyclesuniformpricespricesinfluencedbymanyfactorsspeedisveryimportantspeedissubordinateuniforminventoryvariousinventoriesforvariousproductsproductsexistintheeasy-to-be-managedstagesofthelifecyclerecycledproductsexistincomplicatedstagesdirectnegotiationsamongparticipantsofthesupplychaincomplexandvariantnegotiationprocessreal-timetracingforproductsbeingsaleddifficulttotracehowrecycledproductsaretreatedcanbepredicteduniformlydifficulttobepredictedtransportationisunilateraltomultilateraltransportationismultilateraltounilateralhomogenousqualityofproductsheterogenousqualityofproductsuniformpackagesofproductspackagesofproductsoftendamaged3.

2ComparisonbetweenreverselogisticsnetworkandforwardlogisticnetworkBecauseofthehighersupplyuncertaintyinquality,quantity,timeandsomeotheraspects,reverselogisticsnetworkismuchmorecomplicatedthantraditionalforwardlogisticnetwork.

Regardingsupplychainperformance,Fleischmannpointedoutthedistinctionsbetweenreverselogisticnetworkandforwardlogisticnetwork,i.

e.

recoveryproductshavetobeinspectedandclassificationinreverselogisticswithhigheruncertainty.

TheTaoYeandYinZhenhuaJ.

Chem.

Pharm.

Res.

,2014,6(7):1916-19211918distinctionsshouldbeconsideredindesigningandoptimizingreverselogisticsnetwork[14].

MoredifferencesputforwardbytheresearcherscanbeseeninTable1[15-18].

3.

3CaseStudiesforreverselogisticsnetworkManyresearchershavecarriedoutcasestudiesbecauseareverselogisticsnetworkisusuallycomplicated.

Thecaseswerechosenfromvariousindustriesorproductssuchasbatteryrecycling,paperrecycling,electronicequipment,sandrecyclingandnuclearpower.

.

Avehicleroutingapproachwaspresentedforthetransportofend-of-lifeconsumerelectronicgoodsforrecyclinginSouthKoreatominimizethedistanceoftransportationofend-of-lifegoodscollectedbylocalauthoritiesandmajormanufacturers'distributioncenterstofourregionalrecyclingcenterslocated[19].

Alinearmulti-objectiveoptimizationmodelwasusedtooptimizetheoperationsofboththenuclearpowergenerationandthecorrespondinginducedwastereverselogisticsinChina[20].

Amulti-periodMILPmodelwasestablishedforcarpetrecyclinginEnglandtoanalyzeasetofalternativescenariosidentifiedbythedecisionmakerandprovidedanear-optimalsolutionfornetworkdesign[21].

AnewMILPmodelwasputforwardtooptimizetheinfrastructuredesignandthereversenetworkflowfortherecoveryofelectricalappliancesandcomputersinTaiwan,withcomputationalresultsforthescenariosofdifferentproductreturnratesandoperationconditions[22].

ThereverselogisticsnetworkofanelectronicequipmentremanufacturingfirminAmericawasanalyzed,andamulti-productcapacitatedwarehouselocationMILPwaspresentedandsolvedtoobtainoptimalityfordifferentsupplyanddemandscenarios[23].

AnotherMILPmodelwasestablishedforthemulti-echelonproductrecoverynetworkdesignwhichfocusedontheremanufacturingofacertaintypeofcopyphotocopier[6].

InthisstudyanLPsolverwasalsousedtogettheoptimalsolutionfortheinstancesofsmallproblemsize.

MorecasestudiescanbefoundinTable2.

Table2CasestudiesforreverselogisticsnetworkCaseLiteratureBatteryrecycling[24]Wasteofelectricalandelectronicequipment[5]EOLelectronicandelectronicproducts[25]EOLvehicles[10]Originalequipmentmanufacturers[17]Electronicgoods[19]Paperrecycling[26]EOLcomputerproducts[27]Nuclearpowergeneration[20]Metal-mechaniccompany[14]Carpetrecycling[28]Automotiveindustry[29]Sandrecycling[30]Electronicwaste[31]Wasteofelectricalandelectronicequipment[18]Carpetrecycling[21]Spentbatteries[32]Computersandhomeappliances[22]Electronicequipmentremanufacturingcompany[23]Photocopiers[6]Carpetmaterials[33]Sandrecycling[24]3.

4QuantitativeModelsforreverselogisticsnetworkManyquantitativemodelshavebeenproposedforreverselogisticsnetworkdesignintherecentyears,includingmixedintegerlinearprogramming(MILP)model,mixedintegernonlinearprogramming(MINLP)model,mixedintegergoalprogramming(MIGP)modelandlinearmulti-objectiveprogramming(LMOP)model.

Amulti-objectiveandmulti-periodMILPmodelwasestablishedforreverselogisticnetworkdesignformodularizedproductswhichdeterminesthenumberofexistingforwardflowfacilitiestobeusedandthenumberofdedicatedfacilitiestobesetupforhandlingreturnflows[34].

Amixedintegergoalprogramming(MIGP)modelwasestablishedtodeterminethefacilitylocation,routeandflowofdifferentvarietiesofrecyclablewastepaperinthemulti-item,multi-echelonandmulti-facilityenvironment[26].

AsimulationmodelofareverselogisticsnetworkwasusedtocollectEOLappliances[16].

Withtemporalconsolidationissuesinamultipleplanninghorizon,Minandhiscolleaguesputforwardanonlinearmixedintegerprogrammingmodelandageneticalgorithmtosolvethereverselogisticsprobleminvolvingproductreturnsinothertwoarticles[35].

Anonlinearintegerprogramwasproposedtosolvethemulti-echelon,multicommodityclosedloopnetworkdesignprobleminvolvingproductreturnsinanotherarticleoftheauthors[36].

Alinearmulti-objectiveoptimizationmodelwaspresentedtooptimizetheoperationsofboththenuclearpowergenerationandthecorrespondinginducedwastereverselogistics[37].

TheauthorTaoYeandYinZhenhuaJ.

Chem.

Pharm.

Res.

,2014,6(7):1916-19211919incorporatedfactorssuchastheoperationaldangersinducedinboththepowergenerationandreverselogisticsprocessesinthemodelformulation.

AnMILPmodelwasputforwardtoanalyzetheimpactofproductrecoveryonlogisticsnetworkdesignandaheuristicalgorithmwasappliedtoobtainthesolutionforcaseswithlargeproblemsize[12].

MorequantitativemodelscanbefoundinTable3.

Table3QuantitativemodelsinreverselogisticsnetworkQuantitativemodelLiteratureLinearmulti-objectiveprogramming[20],[37]Mixedintegergoalprogramming[26]Mixedintegerlinearprogramming[38],[39],[25],[40],[11],[41],[42],[43],[44],[45],[30],[34],[21],[46],[4],[22],[23],[6]Mixedintegernonlinearprogramming[47],[35],[36]Amajorissueinthereversedistributionishowtointegrateforwardchannelandreversechannel[4].

Thestructureofreverselogisticsnetworkhasastronginfluenceontheperformanceofforwardlogisticsnetworkandviceversaastheysharealotofresourcessuchastransportandwarehousecapacity.

Separatelydesigningforwardlogisticsandreverselogisticsresultsinsub-optimaldesignswithrespecttocosts,servicelevelsandresponsiveness,sotheintegrationofforwardandreverselogisticsnetworkshasdrawnattentionofmanyresearchers.

Aclosed-loopsupplychain(CLSC)consistsofbothforwardsupplychainandreversesupplychain.

Correspondingly,aclosed-looplogisticnetworkconsistsofbothforwardlogisticnetworkandreverselogisticnetwork.

Bystudyingacaseofphotocopierremanufacturingandacaseofpaperrecycling,Fleischmannpointedoutthatthereispossibilityforcostsavingsifoneundertookanintegratedviewratherthanasequentialdesignoftheforwardandreversedistributionnetworks[4].

Ahybridmethodwasdevelopedtoestablishaclosed-loopsupplychainmodelforspentbatteries.

Themodelincludesatwo-stagefacilitylocationoptimizationproblemandwasappliedunderdifferentscenariosforasteelmakingprocess[32].

Alinearmultiobjectiveprogrammingmodelwasformulatedtooptimizetheoperationsofbothintegratedlogisticsandcorrespondingused-productreverselogisticsinagivengreen-supplychain,withtheconsiderationoftheusedproductreturnratioandcorrespondingsubsidiesfromgovernmental[37].

Agenericstochasticmodelwaspresentedforthedesignofnetworkscomprisingbothsupplyandreturnchannelsinaclosedloopsystem,whichissolvedbytheintegerL-shapedmethod[43].

Atwo(0,1)levelmixedintegerprogrammingmodelofanuncapacitatedfacilitylocationwasproposed,inwhichsimultaneouslyforwardandreverseflowsandtheirmutualinteractionswereconsidered[44].

Thelogisticsnetworkdesignforend-of-leasecomputerproductswasdiscussedandadeterminedprogrammingmodelforsystematicallymanagingforwardandreverseslogisticsflowswasdeveloped[27].

Anintegratedmodelforsupplychainmanagementwasproposed,wheretheoperationofthereversechainhadbeenbuiltbasedontheexistingprocessesoftheforwardchain,andthismodelhadbeenvalidatedinacompanyfromthemetal-mechanicsector[14].

Afacilitylocation-allocationmodelforredesigningclosed-loopservicenetworkofacomputermanufacturerwasdeveloped.

Themodelconsideredthepossibilityofthenetworkspanningacrossseveralcountriesandmulti-periodplanninghorizons[48].

Aclosedloopmixedintegerlinearprogrammingmodelwasdevelopedtodeterminerawmateriallevel,productionlevel,distributionandinventorylevel,disposallevel,andrecyclinglevelatdifferentfacilitieswiththeobjectiveofminimizingthetotalsupplychaincost[38].

Manyreverselogisticnetworkmodelshaveappearedincasestudies,sotheylackgeneralityindifferentsituations.

Someresearchershavetriedtoproposegeneralizedmodels.

Ageneralquantitativemodelwaspresentedforproductrecovery,inwhichrepairingandremanufacturingwereconsideredsimultaneously[42].

Anothergeneralizedmodelofreverselogisticsnetworkwasestablishedasamixedintegerformulation,wherecapacitylimits,multi-productmanagementanduncertaintyonproductdemandsandreturnswereconsidered[45].

Fleischmannandhiscolleaguesalsoputforwardsuchamodelforthedesignofreverselogisticsnetworks,andpresentedageneralizedfacilitylocationmodel(MILP)tointegratetheforwardandreversechainswithabalanceconstraintthatthetotalreturnofeachfactorycannotexceeditstotalproduction[4].

Uncertaintyisanotherimportantcharacteristicofproductrecoverybecausethequantityandthequalityofusedproductsaremoredifficulttocontrolandestimateinreverseflow.

Someresearchershaveaddressedthisissueunderstochasticenvironment.

Aperiodicreviewmodelwasestablishedforproductrecoveryinstochasticremanufacturingsystemswithmultiplereuseoptions[49].

Astochasticprogrammingapproachwaspresentedtogetherwithadeterminedlocationmodelforproductrecoverynetworkdesigntodealwithsomeuncertainties.

However,thisapproachcanonlysolveasmallnumberofscenariosoftheuncertainproblemparameters[30].

Amulti-periodandmulti-echelonforward-reverselogisticsnetworkdesignriskmodelwasdevelopedbyEl-Sayedandhiscolleagues.

Themodelwasformulatedasastochasticmixedintegerlinearprogramming(SMILP)decisionmakingform.

Butitcanonlybeusedforsingleitemandsingleproductproblems[11].

AtwostagestochasticprogrammingmodelwasputforwardbyLeeandhisTaoYeandYinZhenhuaJ.

Chem.

Pharm.

Res.

,2014,6(7):1916-19211920colleagues.

Theyintegratedthesampleaverageapproximationmethodwithaheuristicalgorithmbasedonsystemanalysis[50].

Someresearchershaveusedquantitativemodelstostudyreversenetworkconcerningthird-partylogistics(3PLs).

Thereasonisprobablythattherearemajoradvantagesassociatedwith3PLsprovidershandlingthereverselogisticsforcompanies.

First,the3PLsprovidershaveexpertise,sophisticatedlogisticnetworks,ITtechnologyandthecapabilitytooperatesystemsefficiently[51].

Second,thesameassets(investment)ofthird-partyproviderscanbeusedinvariouscontractualrelationshipsandthusprovideeconomiesofscalewhenemployed[52].

Rupnowandotherresearchersshowedthemultiplebenefitsthatcompaniesusing3PLsservicetypicallyexperience[1].

Themostfrequentlymentionedadvantagesarecostreduction,improvedexpertiseandaccesstodata,improvedoperationandcustomerservicesandtheabilitytofocusoncorecompetenciesandflexibility.

Amixedintegernonlinearprogrammingmodelwasappliedforthedesignofadynamicintegrateddistributionnetworkfor3PLs.

Inordertohandletherealisticallysizedproblem,ageneticalgorithmwaspresented[47].

Aclosedloopreverselogisticsnetworkproblemwasestablishedinwhichmanufacturerstookadvantageofa3PLsystemforthepost-saleservice[40].

Amixed-integerprogrammingmodelandageneticalgorithmwereputforwardtosolvethereverselogisticsprobleminvolvingthelocationandallocationofrepairfacilitiesfor3PLs[41].

CONCLUSIONThispapersummarizestheresearchmethodologyforreverselogisticsnetworkascasestudyandquantityanalysis,andclassifiesreverselogisticsnetworkmodelsintofourmajorcategories:closed-loop,genericmodel,stochasticmodeland3PLs.

Ourreviewshowsthatcasestudyforreverselogisticsnetworkhaskeptahighproportioninthelastdecadewhilequantitymodelandclosed-loopnetworkhavereceivedgrowingattention.

Theproducttypescoveredincasestudyarestillnotextensiveandlimitedinseveralsimilarproducts.

Itisachallengetoextendcasestudyforreverselogisticsnetworktomostproducts.

Moreover,thegeneralityofmodelforreverselogisticsnetworkisnotsatisfactoryastherearealotofdifferentsituationsineachlogisticnetwork.

Inaddition,reverselogisticsnetworkdesignfor3PLshasnotfullybeenaddressed.

AcknowledgementsThisresearchwasfinanciallysupportedbyResearchStartProjectofHangzhouDianziUniversity(KYS035609044).

REFERENCES[1]SSeuring.

DecisionSupportSystems,2013,54(4),1513-1520.

[2]KSubulan;ATasan.

InternationalJournalofAdvancedManufacturingTechnology,2013,66(1),251-269.

[3]GCSouza.

DecisionScience,2013,44(1),7-38.

[4]MFleischmann;PBeullens;JMBloemhof-Ruwaard;LNVWassenhove.

ProductionandOperationsManagement,2001,10(2),156-173.

[5]MGrunow;CGobbi.

CIRPAnnals-ManufacturingTechnology,2009,58(1),391-394.

[6]HRKrikke;AVanHarten;PCSchuur.

ORSpectrum,1999,21(3),381-409.

[7]VJayaraman;YLuo.

AcademyofManagementPerspectives,2007,21(2),56-73.

[8]JELee;KDLee,Kang-Dae.

InternationalJournalofInnovativeComputingInformationandControl,2012,8(7),4483-4495.

[9]SARubio;TChamorro;FJMiranda.

Int.

J.

ofProductionResearch,2008,46(4),1099-1120.

[10]RCruz-Rivera;JErtel.

EuropeanJournalofOperationalResearch,2009,196(3),930-939.

[11]MEl-Sayed;NAfia;AEl-Kharbotly.

Computers&IndustrialEngineering,2010,58(3),423-431.

[12]MFleischmann;HRKrikke;RDekker;SDPFlapper.

Omega,2000,28(6),653–666.

[13]KHarold;CPPappis;GTTsoulfas;J.

Bloemhof-Ruwaard.

ERIMReportSeriesResearchinManagement,2001,62(2),138-147.

[14]MVdelaFuente;LRos,L;MCardos,M.

Int.

J.

ProductionEconomics,2008,111(2),782-792.

[15]SKSrivastava.

InternationalJournalofManagementReviews,2007,9(1),53-80.

[16]SKara;FRugrungruang;HKaebernick.

Int.

J.

ProductionEconomics,2007,106(1),61-69.

[17]AMutha;SPokharel.

Computers&IndustrialEngineering,2009,56(1),334-346.

[18]GWalther;TSpengler.

Int.

J.

ofPhysicalDistributionandLogisticsManagement,2005,35(5),337-361.

[19]HKim;JYang;KLee.

TransportationResearchPartD,14(5),291-299.

[20]JBSheu.

TransportationResearchPartE,2008,44(1),19-46[21]MRealff;JAmmons;DNewton.

IEEEIEEMTransactions,2004,36(8),767-776.

[22]LHShih.

Resources,ConservationandRecycling,2001,32(1),55-72[23]VJayaraman;J.

Guige;RSrivastava.

JournaloftheOperationalResearchSociety,1999,vol.

50,pp.

497-508TaoYeandYinZhenhuaJ.

Chem.

Pharm.

Res.

,2014,6(7):1916-19211921[24]AIBarros;RDekker,R;VScholten.

EuropeanJournalofOperationalResearch,1998,110(2),199-214.

[25]AXanthopoulos;EIakovou.

WasteManagement,2009,29(5),1702-1711.

[26]PKPatia;PVratb;PKumar.

Omega,2008,36(3),405-417[27]DHLee;MDong.

TransportationResearchPartE,2008,44(3),455-474.

[28]MBiehl;EPrater;MJRealff.

Computers&OperationsResearch,2007,34(2)443-463.

[29]FSchultmann;MZumkeller;ORentz,O.

EuropeanJournalofOperationalResearch,2006,171(3),1033-1050.

[30]OListes;RDekker.

EuropeanJournalofOperationalResearch,2005,160(1),268-287.

[31]ANagurney;FToyasaki.

TransportationResearchPartE,2005,41(1),1-28.

[32]FSchultmann;BEngels;ORentz.

Interfaces,33(6),57-71.

[33]DLouwers;BJKip;EPeters;ESouren,E;SDP.

Computers&IndustrialEngineering,1999,36(4),855-869.

[34]RDKusumastuti;R.

Piplani;GLim.

ProceedingsofIEEEinternationalengineeringmanagementconference,1stEdition,IEEE,Singapore,2004;1239-1243.

[35]HMin;CSKo;HJKo.

Computers&IndustrialEngineering,2006,51(2),309-320.

[36]HMin;HJKo;BIPark.

Int.

J.

Logist.

Syst.

Manage.

,2005,1(4),382-404.

[37]JBSheu;YHChou;CCHu.

Transport.

Res.

PartE:Logist.

Transport.

Rev.

,2005,41(4),287-313.

[38]GKannan;PSasikumar;KDevika.

AppliedMathematicalModelling,2010,34(3),655-670.

[39]MIGSalema;APBarbosa-Povoa;AQNovais.

EuropeanJournalofOperationalResearch,2010,203(2),3363-3349.

[40]FDu;GWEvans.

Computers&OperationsResearch,2008,35(8),2617–34.

[41]HMin;HJKo.

Int.

J.

ProductionEconomics,2008,113(1),176-192.

[42]YZhou;SWang.

J.

ofTransportationSystemsEngineeringandInformationTechnology,2008,8(3),71-78.

[43]OListes.

Computers&OperationsResearch,2007,34(2),417-442.

[44]ZLu;NBostel.

Computers&OperationsResearch,2007,34(2),299-323.

[45]MIGSalema;APBarbosa-Povoa;AQNovais.

EuropeanJournalofOperationalResearch,2007,179(3),1063-1077.

[46]FSchultmann;BEngels;ORentz.

Interfaces,2003,33(6),57-71.

[47]HJKo;GWEvans.

Computers&OperationsResearch,2007,34(2),346–366.

[48]RDKusumastuti;RPiplani;GLim.

Int.

J.

ProductionEconomics,2008,111(2),244-260.

[49]KAInderfuth;GKok;SFlapper.

EuropeanJournalofOperationalResearch,2010,133(1),130-152.

[50]DHLee;DDong.

TransportationResearchPartE,2009,45(1),61-71.

[51]SAElliff.

TheJournalofCommerce,2004,12(2).

1-2.

[52]TSkjoett-Larsen.

Int.

J.

ofPhysicalDistribution&LogisticsManagement,2004,30(2),112-127.

- putwww.299pp.com相关文档

- 8.www.299pp.com

- Ilwww.299pp.com

- MAXwww.299pp.com

- spindlewww.299pp.com

- vFQwww.299pp.com

- Int.J.Curr.Microbiol.App.Sci

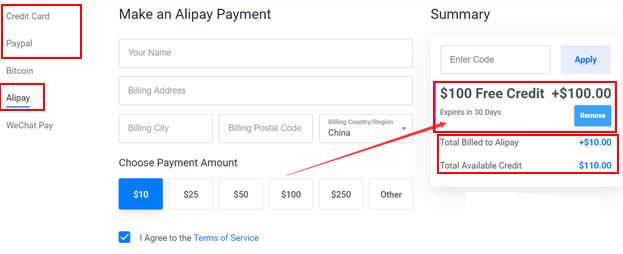

Vultr新注册赠送100美元活动截止月底 需要可免费享30天福利

昨天晚上有收到VULTR服务商的邮件,如果我们有清楚的朋友应该知道VULTR对于新注册用户已经这两年的促销活动是有赠送100美元最高余额,不过这个余额有效期是30天,如果我们到期未使用完的话也会失效的。但是对于我们一般用户来说,这个活动还是不错的,只需要注册新账户充值10美金激活账户就可以。而且我们自己充值的余额还是可以继续使用且无有效期的。如果我们有需要申请的话可以参考"2021年最新可用Vul...

Hostodo独立日提供四款特价年付VPS套餐 最低年付$13.99

前天,还有在"Hostodo商家提供两款大流量美国VPS主机 可选拉斯维加斯和迈阿密"文章中提到有提供两款流量较大的套餐,这里今天看到有发布四款庆祝独立日的七月份的活动,最低年付VPS主机13.99美元,如果有需要年付便宜VPS主机的可以选择商家。目前,Hostodo机房可选拉斯维加斯和迈阿密两个数据中心,且都是基于KVM虚拟+NVMe整列,年付送DirectAdmin授权,需要发工单申请。(如何...

hostio荷兰10Gbps带宽,10Gbps带宽,€5/月,最低配2G内存+2核+5T流量

成立于2006年的荷兰Access2.IT Group B.V.(可查:VAT: NL853006404B01,CoC: 58365400) 一直运作着主机周边的业务,当前正在对荷兰的高性能AMD平台的VPS进行5折优惠,所有VPS直接砍一半。自有AS208258,vps母鸡配置为Supermicro 1024US-TRT 1U,2*AMD Epyc 7452(64核128线程),16条32G D...

www.299pp.com为你推荐

-

AsgardiaGlacia怎么读?是什么意思?沙滩捡12块石头价值近百万捡块石头价值一亿 奇石到底应该怎么定价mathplayer西南交大网页上的 Mathplayer 安装了为什么还是用不了?关键字编程中,什么是关键字xyq.163.cbg.com『梦幻西游』那藏宝阁怎么登录?同一服务器网站一个服务器放多个网站怎么设置?8090lu.com8090lu.com怎么样了?工程有进展吗?www.e12.com.cn上海高中除了四大名校,接下来哪所高中最好?顺便讲下它的各方面情况www.kanav001.com翻译为日文: 主人,请你收养我一天吧. 带上罗马音标会更好wwwpartnersonline电脑内一切浏览器无法打开